Solutions -- Metal Fabrication

Industry Overview

⇲ Growing market size year by year

⇲ Increasing important innovation in technology

⇲ Diversified demands from customers

Metal Fabrication Processes

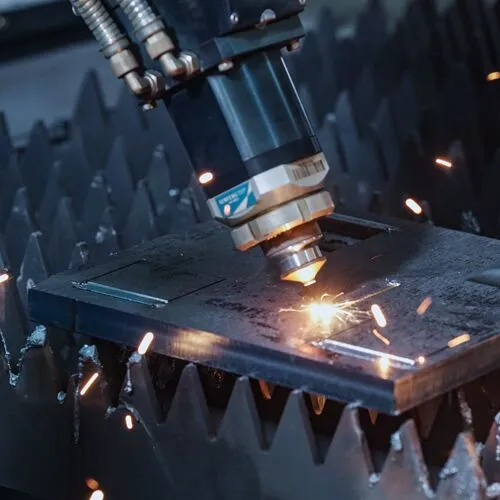

Laser Cutting

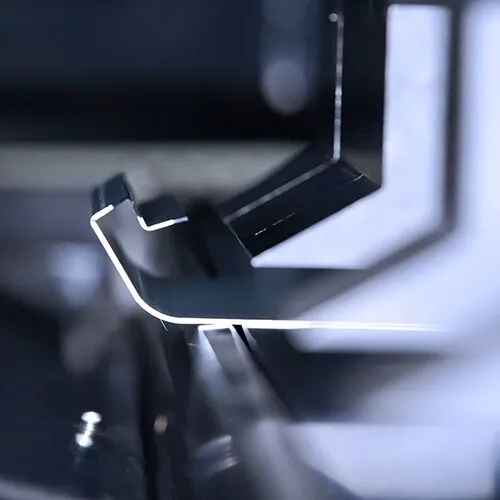

Bending

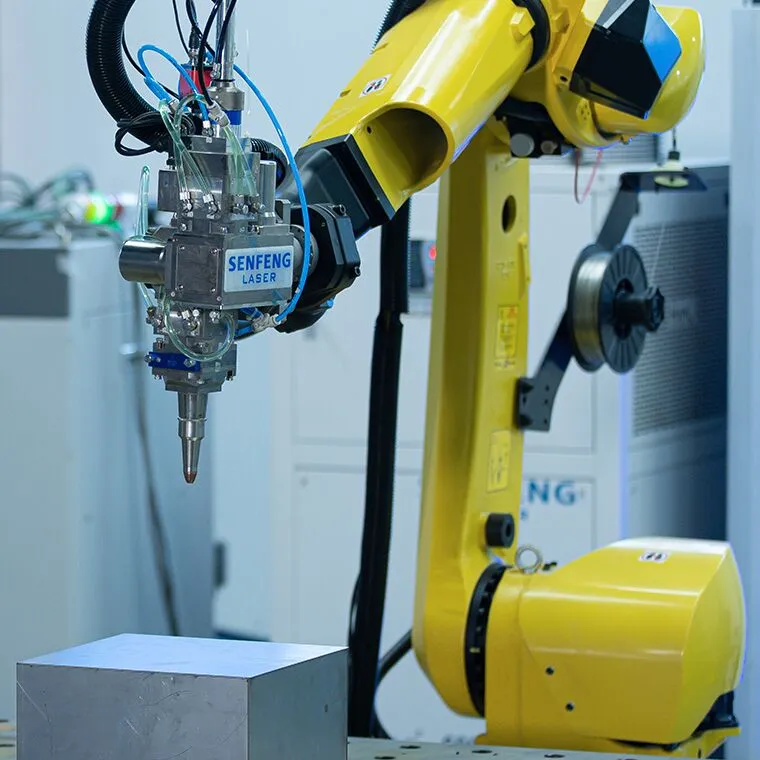

Laser Welding

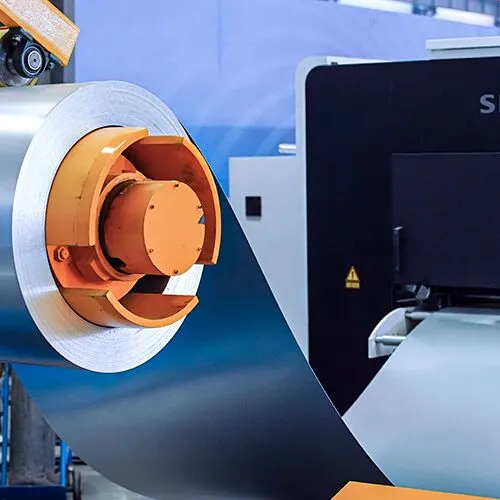

Automation

SENFENG's Advantages

Add Your Heading Text Here

As price war and battle for market share become the norm, higher efficiency usually translates to greater profit margins. SENFENG’s high-power (10kW+) laser cutting machines are faster in cutting, piercing and beveling, helping users curtail production cycle. Automatic production lines utilize robots and other automated devices to achieve non-stop mass production around the clock.

Raise Product Quality

SENFENG can achieve high-precision cutting, bending and welding, improving dimensional accuracy and surface quality of finished products, in order that consistency among workpieces will be ensured. Due to less error arising from human factor, reject ratio is also lowered.

Develop Towards Intelligence and Automation

SENFENG tries to sharpen itself in independent innovation. We have developed intelligent control systems that can monitor and regulate the entire production. As thus, all our production lines become more automatic and intelligent.

Realize Dual Carbon Goals

Currently, global manufacturing industry is transforming towards carbon peaking and carbon neutrality goals. In SENFENG, intelligent manufacturing is gradually taking the place of the tradition. To be specific, energy in using of cutting, bending and welding machines must be cut down, which aligns with current demands for environmental protection.

Relevant Customer Case

⇲ Time of purchase: Nov. 2023

⇲ Specific model: Ultra-large Beveling Laser Metal Cutter SF26040TX

Do you have

any questions?

More Products