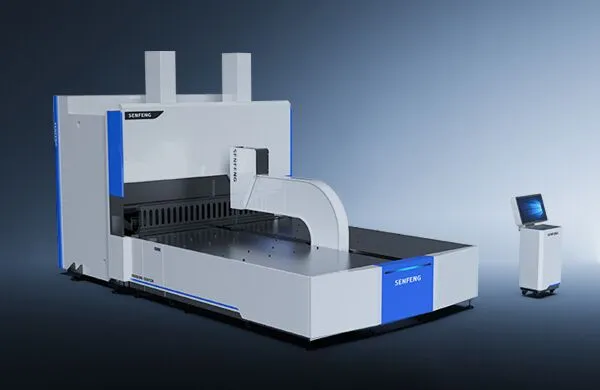

Suction CNC Panel Bender Machine

1500 [mm] Max bending length

1250 [mm] Max bending width

170 [mm] Max bending height

0.2 [S/bend] Max bending speed

Technical Parameters

| Main Parameters | Model | |

| BDC1200 | BDC1500 | |

| Max Bending Speed (S/bend) | 0.2 | 0.2 |

| Max Bending Length (mm) | 1200 | 1500 |

| Bending Height (mm) | 170 | 170 |

| Max Bending Thickness (mm) | 201 stainless steel: 0.8 Cold plate: 1.0 AL sheet: 1.3 |

201 stainless steel: 0.8 Cold plate: 1.0 AL sheet: 1.3 |

| Min Bending Thickness (mm) | 0.35 | 0.35 |

| Max Bending Size (L*W, mm) | 1200*1200 | 1500*1250 |

| Number of Axes | 10-axis concurrent linkage | 10-axis concurrent linkage |

| Rated Voltage (V) | 380 | 380 |

| Total Motor Power (KW) | 30 | 39 |

| Overall Dimensions (L*W*H, mm) | 3700*1800*2450 | 4000*2000*2550 |

| Gross Mass (T) | 9 | 12 |

Competitive Strengths

⇲ Unique design

* The machine is modular and compact in size. Its easy-to-operate functions work with user-friendly design to facilitate the follow-up upgrade and maintenance

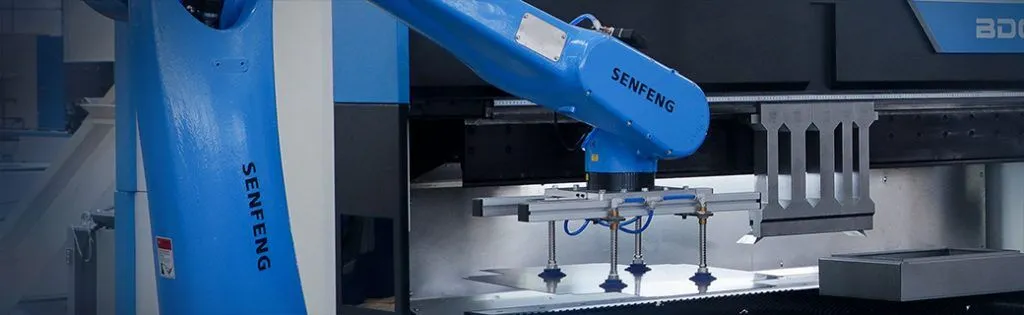

* Its suction-cup loading system uses vacuum suction cups to suck up, move and spin sheets within 360° according to well-setting bending angle

* Its universal bending tools are made of high-strength alloy/die steel and have got through dozens of procedures including solid forging, tempering and quenching in order to bend for millions of times

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Universal bending tools

Bend up & down, arc, dead-edge, U-shaped, enclosed-type bending, as well as bend in right, acute, obtuse angle and other complex shapes

⇲ Unique design

* The machine is modular and compact in size. Its easy-to-operate functions work with user-friendly design to facilitate the follow-up upgrade and maintenance

* Its suction-cup loading system uses vacuum suction cups to suck up, move and spin sheets within 360° according to well-setting bending angle

* Its universal bending tools are made of high-strength alloy/die steel and have got through dozens of procedures including solid forging, tempering and quenching in order to bend for millions of times

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Universal bending tools

Bend up & down, arc, dead-edge, U-shaped, enclosed-type bending, as well as bend in right, acute, obtuse angle and other complex shapes

⇲ Visual graphical programming

Only need to input bending data, then, bending instructions will be generated, with no manual programming

⇲ Cloud maintenance interface

Acquire the machine’s running state, technical process and other data, carry out remote monitoring and failure diagnosis

⇲ Automatic lubrication

Decrease frictional coefficient, lessen abrasion, protect itself from damage and prolong its service life

⇲ Visual graphical programming

Only need to input bending data, then, bending instructions will be generated, with no manual programming

⇲ Cloud maintenance interface

Acquire the machine’s running state, technical process and other data, carry out remote monitoring and failure diagnosis

⇲ Automatic lubrication

Decrease frictional coefficient, lessen abrasion, protect itself from damage and prolong its service life

Recent Posts

Archives

Categories

Related Products

1500 [mm] Max bending length

1250 [mm] Max bending width

170 [mm] Max bending height

0.2 [S/bend] Max bending speed

3200 [mm] Max bending length

1250 [mm] Max bending width

200/300 [mm] Max bending height

0.2 [S/bend] Max bending speed

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments