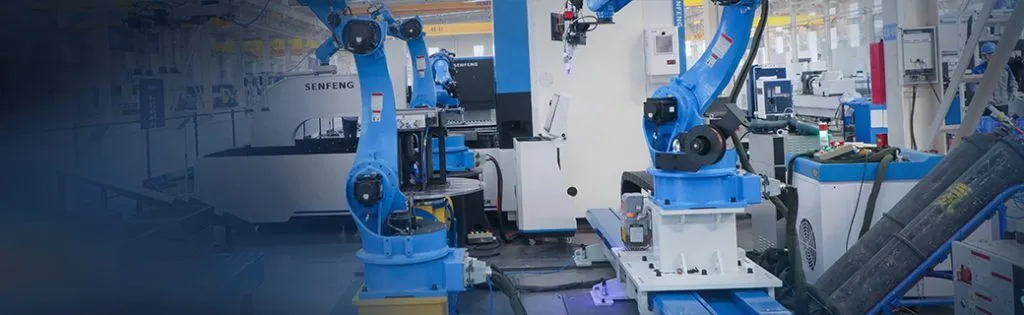

FANUC 3D Robotic Laser Welding Machine

FANUC 3D Robotic Laser Welding Machine

1.5-20 [kW] Laser power

1 [set] FANUC 3D robot

1.6 [mm] Max diameter of filler wire

14 [mm] Max thickness of sheet

Technical Parameters

| Main Parameters | Model | |||||

| SF1500RW | SF2000RW | SF3000RW | SF6000RW | SF12000RW | SF20000RW | |

| Laser Power (kW) | 1.5 | 2 | 3 | 6 | 12 | 20 |

| Laser Wavelength (nm) | 1080 (±10) | 1080 (±10) | 1080 (±10) | 1080 (±10) | 1080 (±10) | 1080 (±10) |

| Thickness of Welding Sheet (mm) | ≤3 | ≤4 | ≤6 | ≤7 | ≤10 | ≤14 |

| Diameter of Filler Wire (mm) | 0.8-1.6 | 0.8-1.6 | 0.8-1.6 | 0.8-1.6 | 0.8-1.6 | 0.8-1.6 |

| Weight of Welding Gun (kg) | ≤2.2 | ≤2.2 | ≤2.2 | ≤8 | ≤8 | ≤8 |

| Max Load of Robot (kg) | 25 | 25 | 25 | 25 | 25 | 25 |

| Fiber Length (m) | 10 | 10 | 20 | 20 | 20 | 20 |

| Robot Armspan (mm) | 1831 | 1831 | 1831 | 1831 | 1831 | 1831 |

| Overall Dimensions (L*W*H, mm) | 482.6*478*128 | 482.6*550*133 | 483*850*172 | 640*1000*700 | 480*950*780 | 750*1100*1070 |

| Power Supply | Three-phase 380V, 50/60HZ | |||||

Competitive Strengths

⇲ 3D welding gun

Its protective lens are drawer-type and easy to replace. Due to fully-sealed structure, it is effectively protected from dust pollution

⇲ Free-standing water chiller

Much safer because of its independent structure; wiring modes up to you, for easy repair

⇲ Stepping wire feeder

Have functions of wire feeding, retraction, replenishment and recovery. Different feeding speeds can be preset according to varying process requirements

⇲ Adapt to different workplaces

Electrical failure rate is low even in the face of high-frequency use and high interference because of our quality electrical elements from international well-known brands

⇲ 3D welding gun

Its protective lens are drawer-type and easy to replace. Due to fully-sealed structure, it is effectively protected from dust pollution

⇲ Free-standing water chiller

Much safer because of its independent structure; wiring modes up to you, for easy repair

⇲ Stepping wire feeder

Have functions of wire feeding, retraction, replenishment and recovery. Different feeding speeds can be preset according to varying process requirements

⇲ Adapt to different workplaces

Electrical failure rate is low even in the face of high-frequency use and high interference because of our quality electrical elements from international well-known brands

⇲ User-friendly interface

Easy to operate and fast to check whether all signals are normal

⇲ Progressive laser output

Minimize weld pits at start and finish points of welding

⇲ Welding craft library

Store and invoke welding parameters at will

⇲ Positioner

Various kinds of positioners available to get the optimal welding position and speed particularly for large or heavy workpiece

⇲ Visual welds tracking system

Compensate the deviation between demonstrating path and actual weld seams automatically

⇲ Voltage stabilizer

Adjust output voltage automatically, smooth out voltage fluctuation and fit for users in areas with unstable power supply

Recent Posts

Archives

Categories

Related Products

1.5-3 [kW] Laser power

7 [mm] Max thickness of sheet

≤0.7 [kg] Weight of welding gun

10 [m] Max length of welding gun’s optical fiber

0.8-1.5 [kW] Laser power

5 [mm] Max thickness of sheet

≤0.7 [kg] Weight of welding gun

7 [m] Max length of welding gun’s optical fiber

1.5-20 [kW] Laser power

1 [set] FANUC 3D robot

1.6 [mm] Max diameter of filler wire

14 [mm] Max thickness of sheet

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments