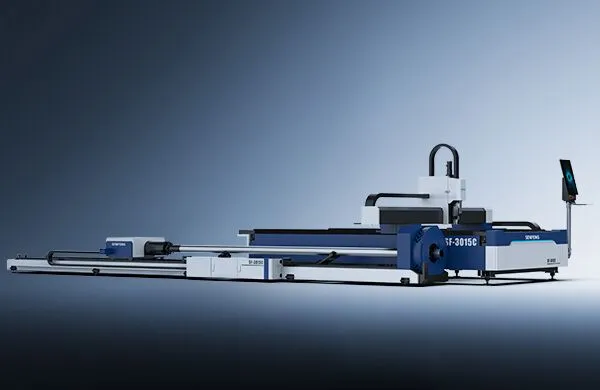

Full Cover Sheet and Tube Laser Cutter

1.5-6 [kW] Laser power

3050*1530-6050*2030 [mm] Sheet size

20~220 [mm] Scope of tube size

2000 [kg] Max load of sheet platforms

Technical Parameters

| Main Parameters | Model | |||

| SF3015HM | SF4020HM | SF6015HM | SF6020HM | |

| Laser Power (kW) | 1.5-6 | 1.5-6 | 1.5-6 | 1.5-6 |

| Sheet Size (L*W, mm) | 3050*1530 | 4050*2030 | 6050*1530 | 6050*2030 |

| Length of Tube (mm) | 500-6000 | 500-6000 | 500-6000 | 500-6000 |

| Scope of Tube Size (mm) | 20~220 | 20~220 | 20~220 | 20~220 |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 | ±0.05 | ±0.05 | ±0.05 |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 |

| Max No-load Speed (m/min) | 130 | 130 | 130 | 130 |

| Max Load of Sheet Platforms (kg) | 700 | 1250 | 1400 | 2000 |

| Overall Dimensions (L*W*H, mm) | 9100*3910*2260 | 10600*4460*2260 | 14737*3910*2260 | 14816*4460*2260 |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) | |||

Competitive Strengths

⇲ Fully-enclosed protective chamber

The machine comes with top cover and four-directional baffles, in order to prevent cutting smoke diffusion during cutting

⇲ Autofocus laser cutting head

The tightly dust-proof head is modular and featured by temperature, air leakage and protective window installation detection

⇲ Aviation-grade AL beam

Light in weight and small in inertia, standing out in dynamic performance. The max no-load speed and acceleration reach up to 130m/min and 1G respectively

⇲ Firm in structure for long service life

* This semi-hollow machine tool is internally unconnected to cut off heat transfer and any effect on cutting precision

* Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Fully-enclosed protective chamber

The machine comes with top cover and four-directional baffles, in order to prevent cutting smoke diffusion during cutting

⇲ Autofocus laser cutting head

The tightly dust-proof head is modular and featured by temperature, air leakage and protective window installation detection

⇲ Aviation-grade AL beam

Light in weight and small in inertia, standing out in dynamic performance. The max no-load speed and acceleration reach up to 130m/min and 1G respectively

⇲ Firm in structure for long service life

* This semi-hollow machine tool is internally unconnected to cut off heat transfer and any effect on cutting precision

* Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

SENFENG intelligent operating system is outfitted with content-rich cutting database that allows data call at any time. Material utilization is usually improved by roughly 98%.

* Large-sized touch screen

User-friendly and clearly show entire cutting process

* Real-time monitoring of core components

Protect software, peripherals, laser generator, etc.

* A variety of operating crafts

Automatic edge search, multi-stage piercing, fly cutting

Optional Benefits

⇲ Servo robot arm for loading

Made of CNC system, robot arm, vacuum suction cups and material rack for automatic loading

Recent Posts

Archives

Categories

Related Products

1.5-6 [kW] Laser power

3050*1530-6050*2030 [mm] Sheet size

20~220 [mm] Scope of tube size

2000 [kg] Max load of sheet platform

1.5-6 [kW] Laser power

3050*1530-6050*2030 [mm] Sheet size

20~220 [mm] Scope of tube size

2000 [kg] Max load of sheet platforms

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments