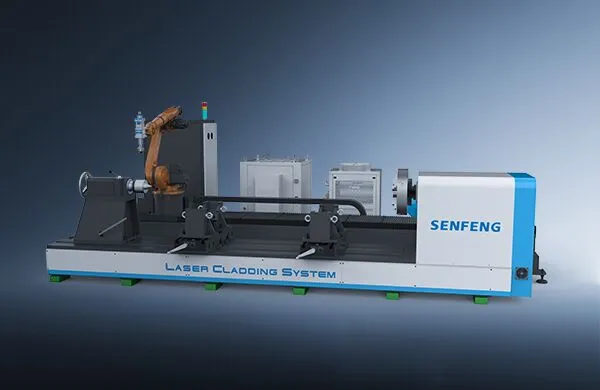

Robotic Laser Cladding Machine SFR6063

6/12 [kW] Laser power

20 [kg] Robot load (optional)

6000 [mm] Max length of workpiece

φ1500 [mm] Max swing of workpiece

Technical Parameters

| Main Parameters | Model |

| SFR6063 | |

| Laser Power (kW) | 6/12 |

| Power Feeder | SENFENG dual-cylinder pneumatic powder feeder |

| Laser Cladding Head | SENFENG high-speed laser cladding head |

| Robot | KUKA/FANUC (optional) |

| Max Load of Robot (kg) | 20 (optional) |

| Max Moving Range of Robot (mm) | 1813 (vary from different brands) |

| Max Load of Table (T) | 15 |

| Max Length of Workpiece (mm) | 6000 |

| Max Clamping Diameter of Workpiece (mm) | Φ630 |

| Max Swing of Workpiece (mm) | Φ1500 |

Competitive Strengths

⇲ Deft design

* Horizontal rotary table is made of high-strength cast iron and featured by high carrying capacity,

good shock absorption and hard deformation

* It is easy for the infinitely variable spindle to control its speed and support the demands of different cladding crafts; with tapered bore, the spindle can work with standard Morse center to realize both clamping and jacking

* The dust-proof tailstock can be easily moved by a worker and serve for a long time but with low failure rate; the tailstock may go up and down, in order to avoid effect on precision caused by friction between itself and machine tool bed

* We adopt heavy-duty horizontal carrier roller to raise its carrying capacity and supporting range

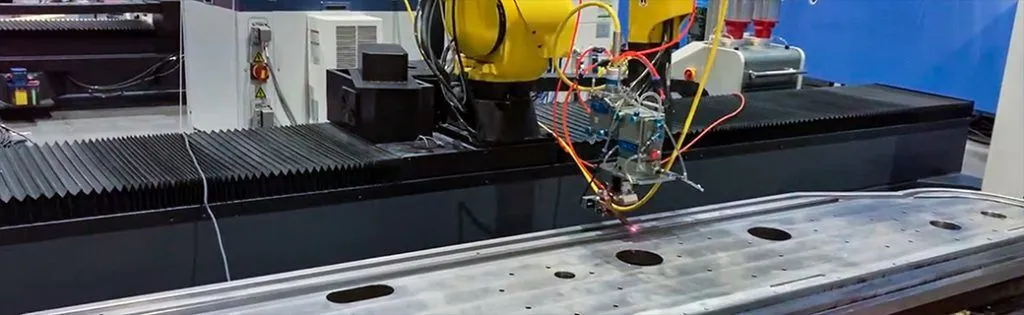

⇲ Automatic robot-assisted cladding

The robot’s traveling shaft enlarges its operating radius and makes the cladding of large and complex workpieces easier

⇲ Multi-purpose laser cladding head

* Our laser cladding head is compatible with annular, four-way, three-way or paraxial power feeding nozzle to offer various laser cladding crafts

* The special internally supercharged gas path and real-time monitoring lens are also used to prevent smoke dust & spatter and prolong its service life

⇲ Dual-cylinder pneumatic powder feeder

* Driven by servo motor, the disc powder feeder is under SENFENG control system for remote control and stable powder feeding

* In addition, powder can be heated and added continuously (optional)

⇲ Deft design

* Horizontal rotary table is made of high-strength cast iron and featured by high carrying capacity,

good shock absorption and hard deformation

* It is easy for the infinitely variable spindle to control its speed and support the demands of different cladding crafts; with tapered bore, the spindle can work with standard Morse center to realize both clamping and jacking

* The dust-proof tailstock can be easily moved by a worker and serve for a long time but with low failure rate; the tailstock may go up and down, in order to avoid effect on precision caused by friction between itself and machine tool bed

* We adopt heavy-duty horizontal carrier roller to raise its carrying capacity and supporting range

⇲ Automatic robot-assisted cladding

The robot’s traveling shaft enlarges its operating radius and makes the cladding of large and complex workpieces easier

⇲ Multi-purpose laser cladding head

* Our laser cladding head is compatible with annular, four-way, three-way or paraxial power feeding nozzle to offer various laser cladding crafts

* The special internally supercharged gas path and real-time monitoring lens are also used to prevent smoke dust & spatter and prolong its service life

⇲ Dual-cylinder pneumatic powder feeder

* Driven by servo motor, the disc powder feeder is under SENFENG control system for remote control and stable powder feeding

* In addition, powder can be heated and added continuously (optional)

⇲ User-friendly operation

The interface is easy to operate. That is, human-machine interaction, laser generator and powder feeding are totally controlled on the CNC system interface.

⇲ Adjust parameters in real time

Laser power and powder feeding speed are adjusted in real time. In other words, you can change cladding parameters at work, with no need for additional shutdown.

⇲ Failure diagnosis

It may detect and output signal feedback in real time. In the event of a failure, automatic alarm will be given in time.

⇲ Fully-covered protective sheet metals

Users are allowed to tailor protective sheet metals outfitted with remote start/stop button and monitoring modules to show actual running state of the machine

⇲ Dual-axis positioner

Help users to get the optimal cladding position and speed particularly for large or heavy workpieces

⇲ Offline software

Offline programming available to help out with the programming of special-shaped workpieces

⇲ Inner-hole cladding head

Clad inner hole with min diameter of φ60mm

Recent Posts

Archives

Categories

Related Products

6/12 [kW] Laser power

20 [kg] Robot load (optional)

6000 [mm] Max length of workpiece

φ1500 [mm] Max swing of workpiece

6/12 [kW] Laser power

2 [T] Max load of table (no carrier roller)

6000 [mm] Max length of workpiece

Φ800 [mm] Max swing of workpiece

6 [kW] Laser power

20 [kg] Robot load (optional)

20-300 [μm] Powder size

150 [g/min] Max power feeding speed

6/12 [kW] Laser power

20 [kg] Robot load (optional)

6000 [mm] Max length of workpiece

φ1500 [mm] Max swing of workpiece

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments