High-Precision Vertical Machining Center CNC Milling Machine

1000*550-1600*800 [mm] Worktable size

6000/8000 [r/min] Max speed of spindle

24 [cutter] Tool magazine capacity

2.5 [s] Tool changing time

Technical Parameters

| Main Parameters | Model | ||||||

| SF-VL855 | SF-VL1160 | SF-VL1160P | SF-VL1370 | SF-VL1580 | SF-VL1690 | ||

| Worktable | Dimensions (mm) | 1000*550 | 1200*600 | 1200*600 | 1400*700 | 1600*800 | 1600*800 |

| Max Load (kg) | 500 | 800 | 800 | 800 | 1500 | 1500 | |

| T-slot Size (mm) | 5-18-90 | 5-18-100 | 5-18-100 | 5-18-130 | 7-22-110 | 7-22-110 | |

| Processing Range | 3-axis Travel (mm) | 800*550*550 | 1100*600*600 | 1100*600*600 | 1300*700*750 | 1500*800*700 | 1600*900*700 |

| Distance from Spindle Nose to Table Surface (mm) | 120-670 | 120-720 | 120-720 | 120-870 | 160-860 | 150-850 | |

| Distance from Spindle Center to Z-axis Guideway Surface (mm) | 590 | 650 | 650 | 722 | 855 | 910 | |

| Spindle | Taper Hole (7:24) | BT40 Φ150 | BT40 Φ150 | BT40 Φ150 | BT40 Φ150 | BT50 Φ155 | BT50 Φ190 |

| Speed Range (r/min) | 8000 | 8000 | 8000 | 8000 | 6000 | 6000 | |

| Feed | 3-axis Rapid Speed (m/min) | 32/32/24 | 24/24/18 | 36/36/24 | 24/24/18 | 24/24/24 | 20/20/12 |

| Feed Speed (mm/min) | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | 1-10000 | |

| Disc Tool hanger | Capacity | 24T | 24T | 24T | 24T | 24T | 24T |

| Tool Changing Time (s) | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | |

| Positioning Accuracy | X/Y/Z-axis Positioning/Repositioning Accuracy (mm) | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 | 0.008/0.005 |

Competitive Strengths

⇲ Compact in structure

* The machine is compact in size. Its small footprint requires tiny working space

* With modular structure, it is easy to repair and replace faulty parts when needed

* Its full cover and front pulling door keep workers informed of work progress anytime

⇲ Hi-end tool magazine

The machine comes with 24T disc tool magazine and automatic tool changer (2.5s only each time) to keep the magazine stable

⇲ Machine tool at high strength

* The machine tool is featured by low vibration and high rigidity after going through rough machining, natural & secondary aging and finish machining; Its one-piece base, made of gray cast iron outperforms in load, capacity, rigidity and abrasion resistance

* Large-span humanoid column is internally outfitted with reinforcing bars to become more resistant to bending and torsion and work more stably at fast-speed milling

* The chrome-molybdenum alloy steel spindle has been subject to thermal treatment and precision grinding and equipped with air shaft seal

* 3-axis lead screw can make sure of high positioning and repositioning accuracy thanks to pre-stretching process

* The central forced lubricating pump is also employed to lubricate all moving parts in time

⇲ User-friendly design

* Its operating panel can rotate to the desired optimal angle at will for easy operation

* The maximally opened front pulling door facilitates both loading and unloading

* Inside the machine tool, the forward-tilting base tray works with flushing fluid and automatic shavings cleaner to remove shavings instantly. It can prevent machine body deformation caused by heat conduction

* Water-proof base tray and side window have undergone 48h continuous leak-proof tests

* High-volume water tank with multi-stage filtration will recycle milling liquids and save relevant costs

* Basket-type filter box helps to remove built-up shavings

⇲ Compact in structure

* The machine is compact in size. Its small footprint requires tiny working space

* With modular structure, it is easy to repair and replace faulty parts when needed

* Its full cover and front pulling door keep workers informed of work progress anytime

⇲ Hi-end tool magazine

The machine comes with 24T disc tool magazine and automatic tool changer (2.5s only each time) to keep the magazine stable

⇲ Machine tool at high strength

* The machine tool is featured by low vibration and high rigidity after going through rough machining, natural & secondary aging and finish machining; Its one-piece base, made of gray cast iron outperforms in load, capacity, rigidity and abrasion resistance

* Large-span humanoid column is internally outfitted with reinforcing bars to become more resistant to bending and torsion and work more stably at fast-speed milling

* The chrome-molybdenum alloy steel spindle has been subject to thermal treatment and precision grinding and equipped with air shaft seal

* 3-axis lead screw can make sure of high positioning and repositioning accuracy thanks to pre-stretching process

* The central forced lubricating pump is also employed to lubricate all moving parts in time

⇲ User-friendly design

* Its operating panel can rotate to the desired optimal angle at will for easy operation

* The maximally opened front pulling door facilitates both loading and unloading

* Inside the machine tool, the forward-tilting base tray works with flushing fluid and automatic shavings cleaner to remove shavings instantly. It can prevent machine body deformation caused by heat conduction

* Water-proof base tray and side window have undergone 48h continuous leak-proof tests

* High-volume water tank with multi-stage filtration will recycle milling liquids and save relevant costs

* Basket-type filter box helps to remove built-up shavings

⇲ LCD color display screen

10.4-inch screen to showcase its rich preset functions

⇲ Graphic simulation

Graphically simulate the moving path of cutters

⇲ Automatic alarm

Record alarm time and details automatically, so that users will find out alarm causes instantly

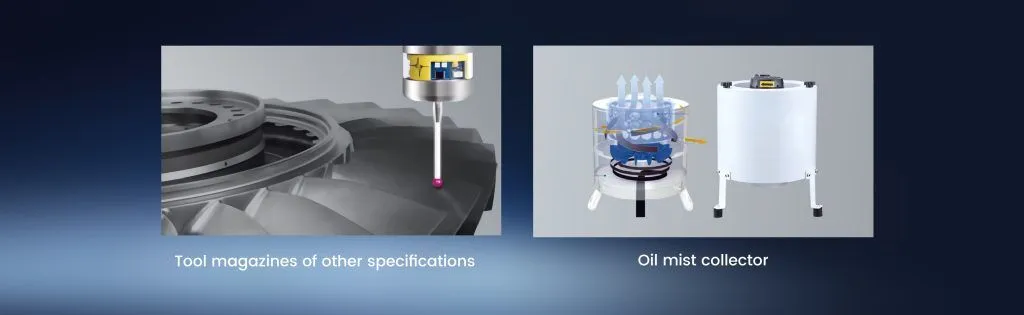

⇲ Tool magazines of other specifications

Other 30T tool magazines are also provided as optional accessories to offer cutters of different weights, lengths and outer diameters

⇲ Oil mist collector

Collect and purify oil mist, water mist and other hazardous substances at work, in this way, minimize workshop pollution and protect workers well

Recent Posts

Archives

Categories

Related Products

360 [mm] Max cutting diameter

500 [mm] Max cutting length

50-4000 [r/min] Rotating speed of spindle

500 [kg] Max loading capacity

1000*550-1600*800 [mm] Worktable size

6000/8000 [r/min] Max speed of spindle

24 [cutter] Tool magazine capacity

2.5 [s] Tool changing time

- 123-456-7890

This Headline Grabs Visitors’ Attention

A short description introducing visitors to your business and the services you offer

About Us

Use this section to describe your company and the services you offer. You could share your company’s story and details about why you are in business. The goal is to create a connection with the visitor and give them confidence to work with you.

Our Services

This text briefly introduces visitors to your main services.

Service 1

A short description of the service and how the visitor will benefit from it.

Service 2

A short description of the service and how the visitor will benefit from it.

Service 3

A short description of the service and how the visitor will benefit from it.

Service 4

A short description of the service and how the visitor will benefit from it.

Why Choose Us

benefit 1

A short description of the benefit.

benefit 2

A short description of the benefit.

benefit 3

A short description of the benefit.

benefit 4

A short description of the benefit.

Client Testimonials

A Title to Turn the Visitor Into a Lead

© 2026 All Rights Reserved.

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments