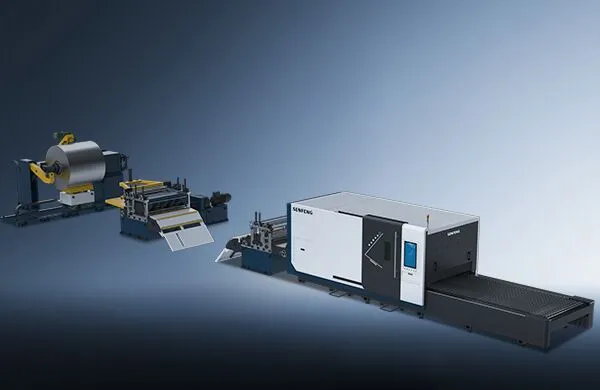

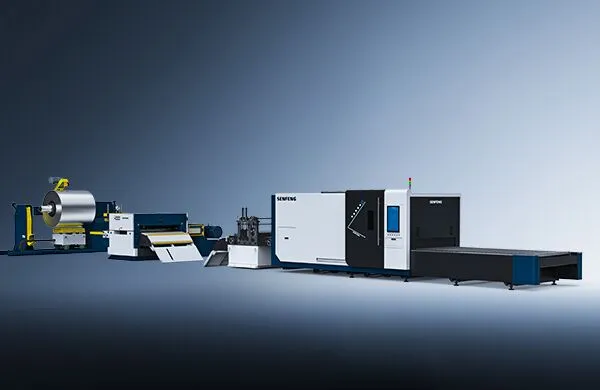

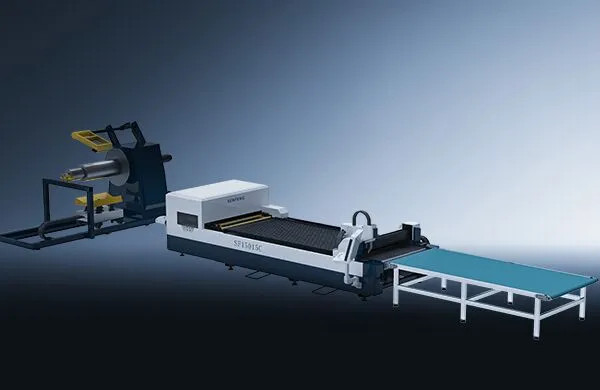

Coil Laser Cutting Machine For 0.6-3mm Steel

1.5-6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

Technical Parameters

| Main Parameters | Model | |

| SF1503CH | ||

| Decoiling and Leveling Unit | Size of Sheet Coil (L*W, mm) | 3000*1500*3 |

| Standard inner diameter of sheet coil (mm) | Φ508 | |

| Max outer diameter of sheet coil (mm) | Φ1400 | |

| Weight of Sheet Coil (T) | 10 | |

| Max Feeding Speed (m/min) | 10 | |

| Leveling Accuracy (mm/m²) | ±2 | |

| Laser Cutting Machine | Laser Power (kW) | 1.5-6 |

| Working Area (L*W, mm) | 3000*1500 | |

| X/Y-axis Positioning Accuracy (mm/m) | ±0.05 | |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 | |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) | |

Competitive Strengths

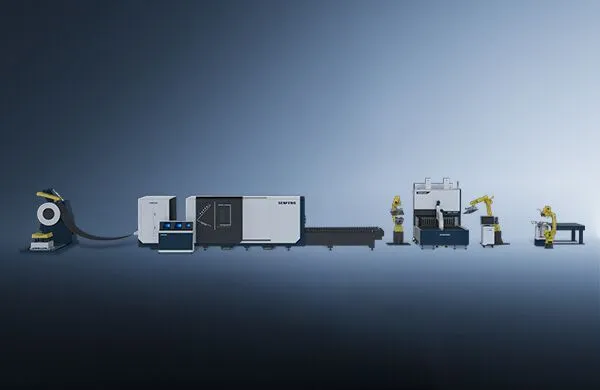

⇲ Automatic assembly line

This assembly line is fully automatic, with no manual intervention from automatic loading, decoiling, leveling, feeding, cutting to unloading device. 30% faster than before at least and realize 0 waste as much as possible

⇲ International famous components

* Heavy-duty decoiling, feeding and leveling unit with steady structure and high carrying capacity

* New fiber laser generator outfitted with anti-reflectivity protection and high electro-optical conversion rate

* Fully-enclosed laser cutting head can prevent dust pollution effectively

* The cutting unit uses multiple sets of AC servo motors for faster response and more accurate control

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Protect both man and machine

* There are more than one set of safety monitoring systems. Its whole process is clear at a glance. If abnormal, alarm will be given in time to prevent unforeseen shutdown

* Adopt protective measures to avoid misoperation and users may cut off the power at full speed in case of emergency

* Electrical system has high capacity of resisting disturbance and automatic diagnosis to find the cause of failure quickly

⇲ Automatic assembly line

This assembly line is fully automatic, with no manual intervention from automatic loading, decoiling, leveling, feeding, cutting to unloading device. 30% faster than before at least and realize 0 waste as much as possible

⇲ International famous components

* Heavy-duty decoiling, feeding and leveling unit with steady structure and high carrying capacity

* New fiber laser generator outfitted with anti-reflectivity protection and high electro-optical conversion rate

* Fully-enclosed laser cutting head can prevent dust pollution effectively

* The cutting unit uses multiple sets of AC servo motors for faster response and more accurate control

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Protect both man and machine

* There are more than one set of safety monitoring systems. Its whole process is clear at a glance. If abnormal, alarm will be given in time to prevent unforeseen shutdown

* Adopt protective measures to avoid misoperation and users may cut off the power at full speed in case of emergency

* Electrical system has high capacity of resisting disturbance and automatic diagnosis to find the cause of failure quickly

⇲ Follow-up control

Adjust follow-up height from cutting head to sheet automatically to eliminate the impact on cutting effects of uneven sheets

⇲ Lightning-fast piercing

Pierce at top speed and enhance efficiency especially when cutting thin sheet

⇲ Recut from break point

Remember the cutting position after power outage, start recut from break point once power recover, thus avoiding material waste

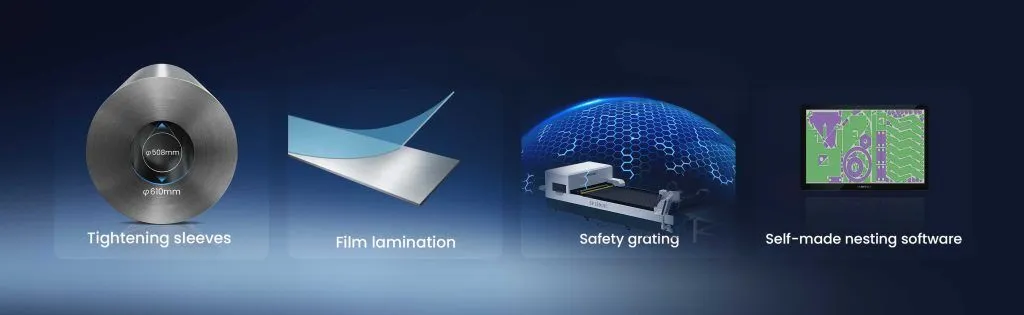

⇲ Tightening sleeves

Decoil sheet coil of φ610mm inner diameter

⇲ Film lamination

Prevent metal surface from scratch after leveling

⇲ Safety grating

Protect both man and machine by warding off accidents

⇲ Self-developed nesting software

Nest and typeset in full volume to maximize material utilization

Recent Posts

Archives

Categories

Related Products

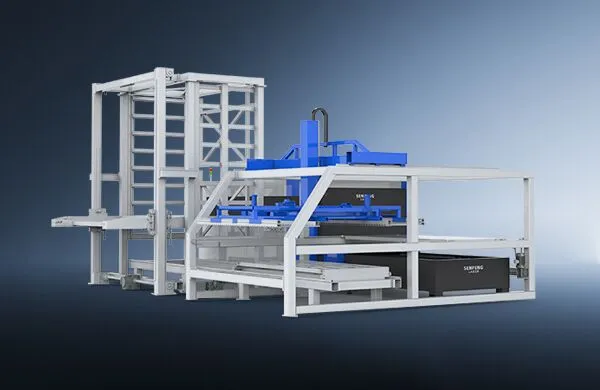

8 [layers] Stereo pallet racks

3000 [kg] Carrying capacity of each layer

3000*1500 [mm] Sheet size

10 [m/min] Warehouse-in/out speed

3000 [mm] Max feeding length

1500 [mm] Max width of sheet coil

3 [mm] Max thickness of coiled sheet

10 [T] Max weight of sheet coil

1.5-6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

1.5 [kW] Laser power

3000*1500 [mm] Working area

0.6-1.2 [mm] Thickness of sheet coil

10 [T] Max weight of sheet coil

6 [kW] Laser power

4000*2000 [mm] Working area

8-14 [mm] Thickness of coiled sheet

20 [T] Max weight of sheet coil

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments