Solutions -- New Energy

Industry Overview

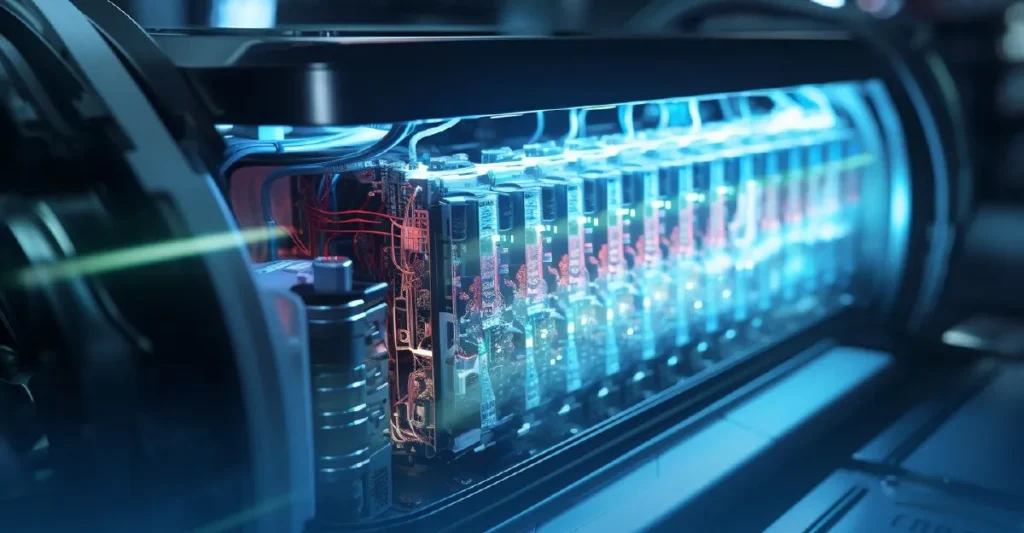

Laser technology is an advanced manufacturing tool and plays a significant role in all stages of new energy battery production lines due to its high efficiency, precision, flexibility, reliability, low material waste, high automation and safety.

Machining Crafts

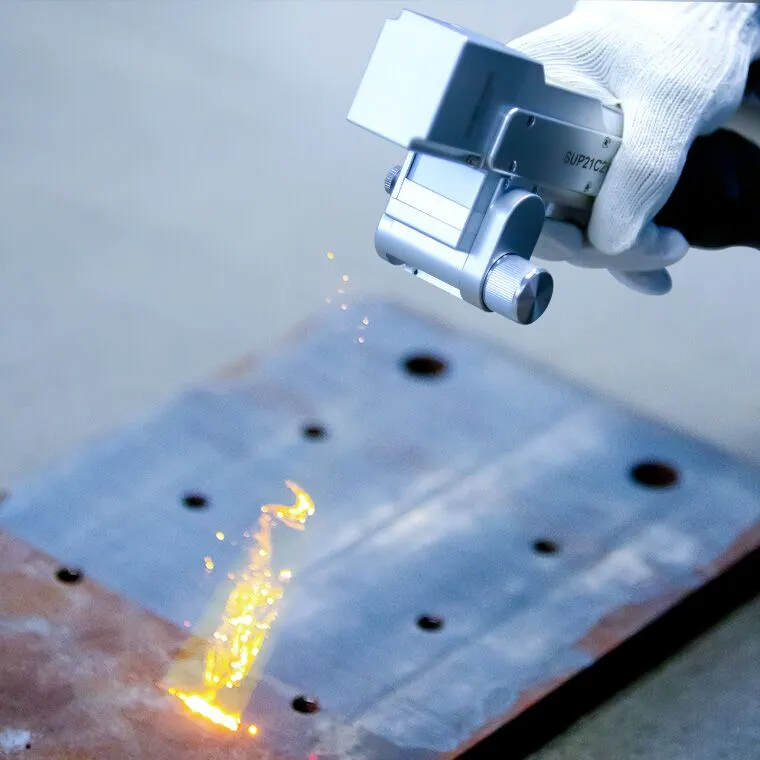

Laser Cutting

Laser Welding

Laser Cleaning

Automation

SENFENG's Advantages

Diversified Products

SENFENG’s new energy production lines can offer various new energy products, incl. prismatic battery, battery modules, battery pack, liquid-cooled energy storage prismatic battery modules, cylindrical battery module pack and energy storage container. Such diversified products provide users with more choices.

Accept Customization

Currently, various new energy manufacturing machines are emerging, but, market demands must be given priority when purchasing. All of SENFENG’s production lines can be customized as needed, supporting the production of batteries of different specifications, sizes and performance from different regions and markets.

Rapid Response to Market Demands

As we all know, the market is unpredictable, and rapid adaptation to market changes is the key to success or failure. We have used reconfigurable module-based new energy production lines to switch among new energy products of different types and specifications rapidly.

Environmentally Friendly

Productive pollution is always troubling most manufacturers. SENFENG’s new energy production lines use eco-friendly materials, energy-saving devices and recycling technologies to reduce energy consumption and waste emissions, making new energy truly green.

Metal processing case

⇲ Time of purchase: Jan. 2024

⇲ Specific model: Fully Automatic Sodion Production Line

Do you have

any questions?

More Products