Solutions -- Kitchenware

Industry Overview

⇲ Stainless steel kitchenware

⇲ Galvanized steel kitchenware

⇲ Die-cast aluminum alloy kitchenware

⇲ Brass kitchenware

⇲ Iron kitchenware

Metal Fabrication Processes

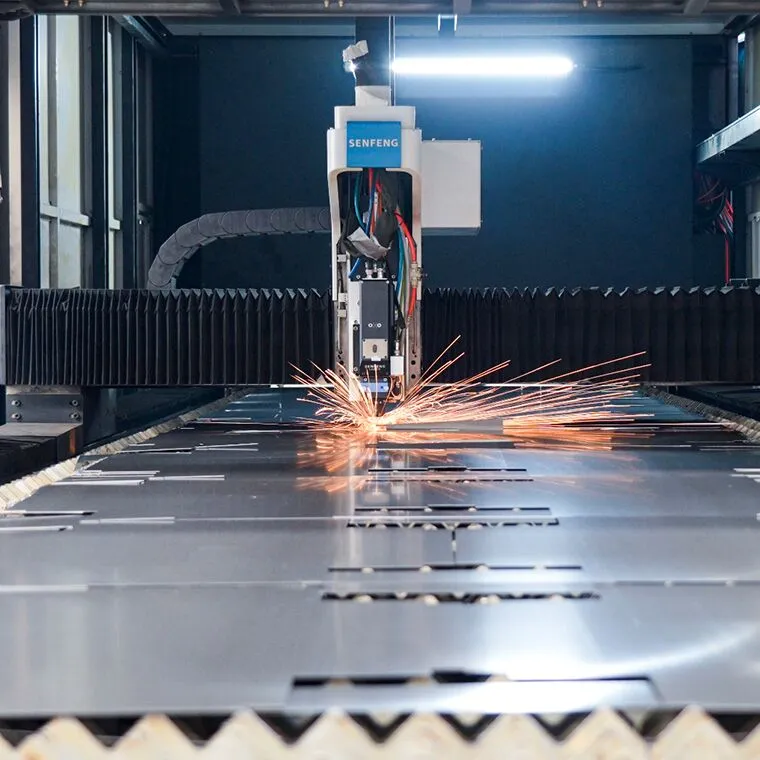

Laser Cutting

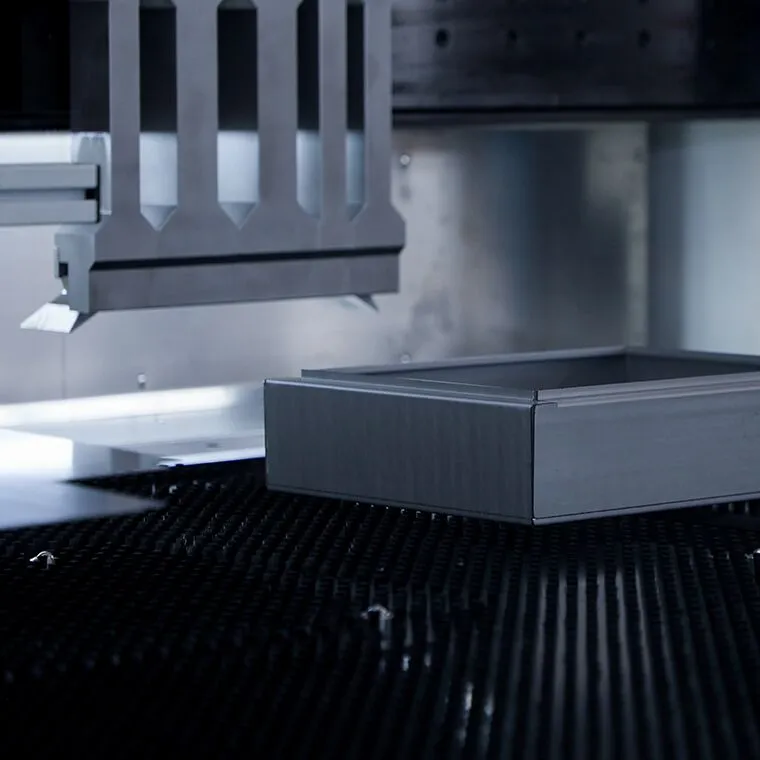

Bend into shape

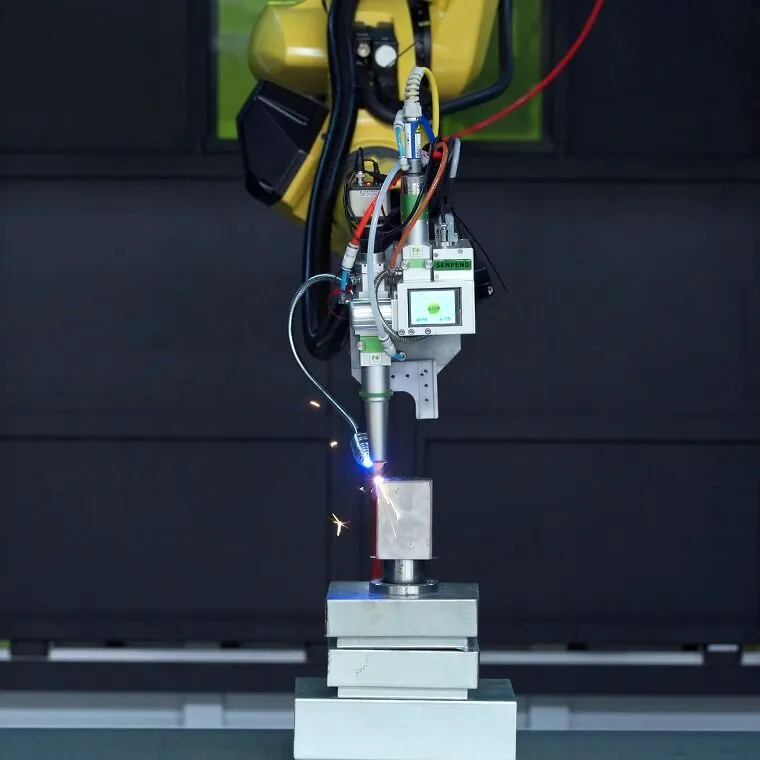

Laser Welding

SENFENG's Advantages

Meet the Demands for Small Kitchenware

Due to changes in family demographics, people are gradually cultivating frugal consumption habits in dining sector. An increasing demand for small kitchenware comes out, which has become essential in both household and commercial fields. Processing precision is crucial when producing small kitchenware. At SENFENG, laser can focus into extremely small spots for fine and precise processing, such as micro-narrow seams (0.1-0.3mm) and micro-hole processing. Whether simple or complex kitchenware, it can be cut and formed in one go with laser, fully meeting user requirements for processing speed and precision.

Make Challenging Delivery Easier

SENFENG use CNC programming to achieve automatic typesetting and nesting, which not only improves material utilization but also allows for cutting of large-format sheet as a whole, metal plate cutting for cabinets, cutting spatula into shape, as well as engraving and punching for various small kitchenware. With such high level of flexibility, we are able to meets market demands for high-mix, small-batch, customized, high-quality and short delivery times.

Reduce Investment Costs

In modern kitchenware production, laser processing has become an essential new technology to achieve efficient production and high-end kitchenware. SENFENG’s laser blanking line frequently used by kitchenware production features minimal space occupation, low investment costs and low energy consumption, making it well-suited to meet the needs of small and medium-sized kitchenware manufacturing enterprises in terms of both initial investment and later maintenance costs.

Ultra-high Cost Performance

SENFENG laser cutting machines require no clamping fixtures during operation, saving on tooling costs and additional time for loading and unloading. During laser cutting, the cutting head doesn’t contact the workpiece, which eliminates tool wear. While bending workpieces of different shapes, it is needless to change bending tools. Only lasers parameters need to be adjusted. In addition, the whole work process is low in noise, vibration and pollution, making kitchenware production be a saver of time and strength.

Relevant Customer Case

This customer is a benchmark enterprise in Chinese kitchenware industry, which has been experiencing robust growth in recent years. However, said by its manager, given the progress of the times and the development of technology, traditional manufacturing industry must keep pace with the times. Although the enterprise has not yet reached a bottleneck period, preparing in advance can always keep it at the forefront of the industry.

To this end, it decided to introduce the most frequently used sheet coil laser cutting machine and flexible panel bender from SENFENG. We customize some functions and core components at the request of the manager. After installation, debugging and trial operation, the manager reported that the company’s production efficiency has increased by 50%, labor costs have decreased by 70%, and the safety of workers is fully ensured at work.

⇲ Time of purchase: Oct. 2022

⇲ Specific model:

2012H Series Coil Laser Blanking Line For 8-14mm Steel

BDC2500 Series Press-down Arm Panel Bender Machine

Do you have

any questions?

More Products