Solutions -- Iron Tower

Industry Overview

⇲ Power transmission tower

⇲ Microwave communication tower

⇲ Television tower

⇲ Decorative tower

⇲ Wind power tower

⇲ Electrified railway pillar

Metal Fabrication Processes

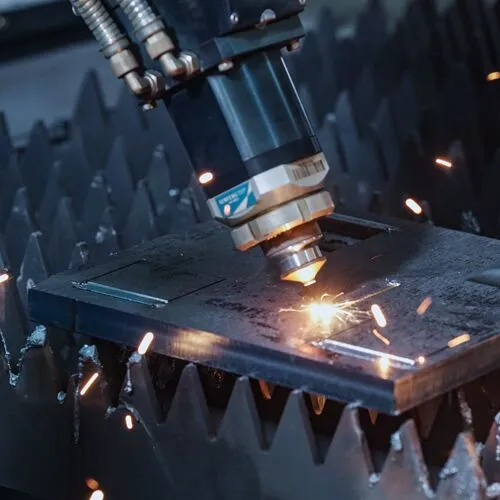

Laser Cutting

Bending

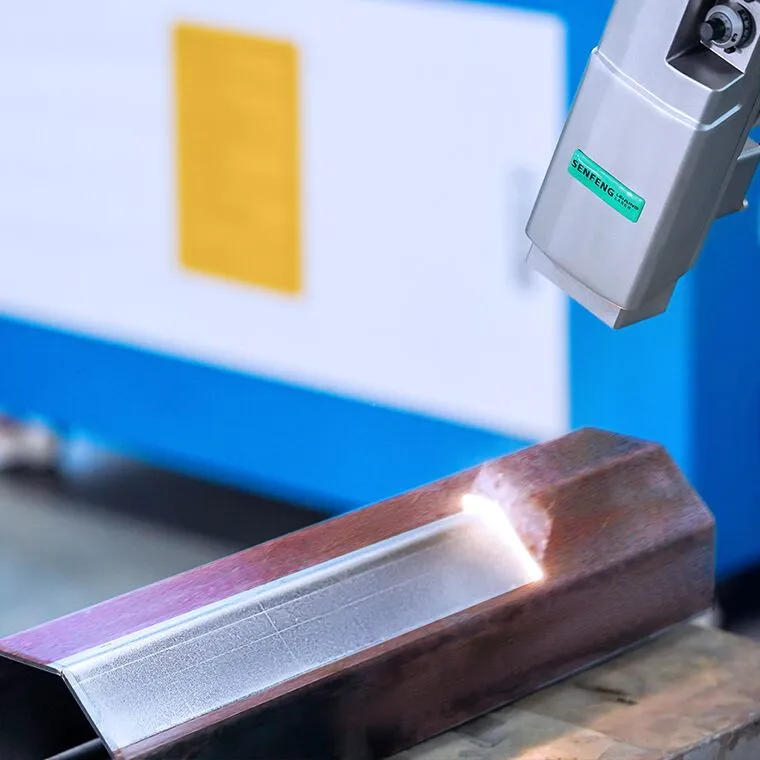

Laser Welding

Laser cleaning

SENFENG's Advantages

Cut Ultra-long Workpieces

According to actual needs, iron tower is generally trapezoidal or triangular in shape, with a height of 25-40m. This task is quite challenging for traditional metalworking equipment. However, SENFENG has developed laser cutting machines and tandem CNC press brakes capable of dealing with ultra-long workpieces, meeting the practical needs of iron tower users.

Align with Tower Production Needs

During production, iron tower is consist of angle steel, round steel, steel pipe, lightweight aluminum alloy, decorative stainless steel plate or various profiles. All these metal materials fall within the processing range of our sheet and tube laser cutting machines, which can meet the vast majority of tower manufacturing requirements.

Keep Iron Tower Stable

Tower body has several sections and they are connected with each other by using bolts or welding. After welding with SENFENG laser welding machines, weld seams are aesthetically pleasing, and the workpieces are less prone to deformation. Sometimes, the welding strength even exceeds that of its base metal. When iron tower is exposed to outdoor conditions for extended periods, they can resist the erosion from direct sunlight, strong winds and heavy rain, preventing accidental breakage and extending its service life.

Achieve Intelligent Production

Tower manufacturers face diverse specifications of raw materials and numerous components throughout the production, necessitating effective management methods to standardize the entire workflow. SENFENG has introduced the concept of intelligent manufacturing to link information management system with production machines in order to facilitate communication. When production plans change, adjustment can be made swiftly, so that a fully information-based and intelligent process will run through raw material supply to shipment.

Relevant Customer Case

In Jul. 2023, a domestic power equipment manufacturing company decided to purchase a tube laser cutting machine and a large-format sheet laser cutting machine after visiting SENFENG’s production base. This customer mainly produces power tower and photovoltaic bracket. Previously, they used plasma cutting and drilling machines, which resulted in low efficiency and accuracy.

After reaching cooperation with us, it can deal with iron tower connecting parts, flange reinforcements, flange plates and other workpieces quickly, achieving one-stop functions such as cutting, hole making and numbering. This not only improved the workpiece precision but also significantly increased efficiency, greatly reducing both labor costs and process transition expenses. Two machines below are useful for its cost decreases and benefit increases.

⇲ Time of purchase: Jul. 2023

⇲ Specific model:

TX Series Ultra-large Beveling Laser Metal Cutter

GT Series Bevel Tube Laser Cutting Machine

Do you have

any questions?

More Products