Solutions -- Engineering Machinery

Industry Overview

Engineering machinery industry is the fundamental pillar of a country and holds an important position in the national economy. It mainly includes sub-sectors like excavator, crane and concrete machinery, with its products widely used in fields such as national defense, transportation, energy, mining, agriculture, forestry, water conservancy and construction. In recent years, the engineering machinery industry has been continuously developing by adopting new technologies and materials to enhance their performance and competitiveness. However, it also faces several challenges, such as intense market competition and an urgent need for technological innovation.

Metal Fabrication Processes

As an important and energetic sector, the industry involves various metal fabrication processes. With fast development and widespread use of laser, traditional metalworking is gradually replaced or supplemented by laser technology. Currently, the following processes are mainly used by this industry.

Laser Cutting

Bend into shape

Laser welding

Automation

SENFENG's Advantages

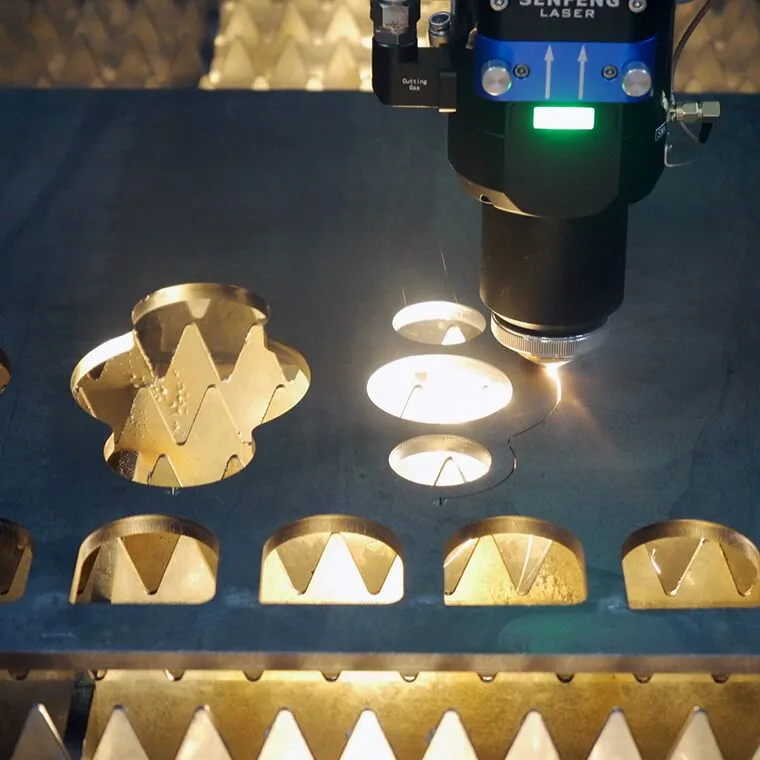

Expert in Cutting Special Workpieces

Typically, the engineering machinery industry requires large, thick and heavy workpieces, as well as irregular structures such as hole- and bevel-shaped types. In response, SENFENG has developed several ground-rack (beveling) laser cutting machines specifically designed to cut over-sized (30000*4000mm), ultra-thick (90mm), and super-heavy (47000kg) metal plates. This not only enables the processing of metal materials in complex shapes and at high precision but also enhances cutting efficiency and quality.

Mass Production at High Efficiency

For engineering machinery, the precision requirements are not high, but due to the large size of workpieces and complex processes, working efficiency is generally low, making mass production difficult. At SENFENG, although there may be slight slag on bottom of workpieces after cutting, bending and welding, it can be completely covered by using subsequent welding, sandblasting, and painting. Therefore, with SENFENG’s automated laser machines, engineering machinery can be completed in batch.

Provide One-stop Solutions

From cutting, bending, welding, cleaning to automation, SENFENG offers customer lifetime value. In the engineering machinery industry, the required workpieces can be processed from raw materials to finished products in a one-stop manner, streamlining work procedures and improving work efficiency, thus alleviating customers’ concerns.

Reduce Material Waste

SENFENG leverages the advantages of low heat impact, narrow cutting seams and non-contact operation during laser processing to effectively reduce material waste and environmental pollution, which aligns with the global trend of sustainable development.

Relevant Customer Case

The user, established in 2015, is a well-known manufacturer located in New Zealand, specializing in machinery for road surface construction and maintenance, incl. asphalt sprayer and asphalt concrete paver.

Looking ahead to 2024, it plans to upgrade equipment to further enhance efficiency and meet the increasing demands. After several rounds of market research, they ultimately selected the SENFENG’s TX series ultra-large beveling laser metal cutter that creates the higher efficiency and precision while cutting sheets required by machines above.

⇲ Time of purchase: May. 2024

⇲ Specific model: TX Series Ultra-large Beveling Laser Metal Cutter

Do you have

any questions?

More Products

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470