PRODUCT

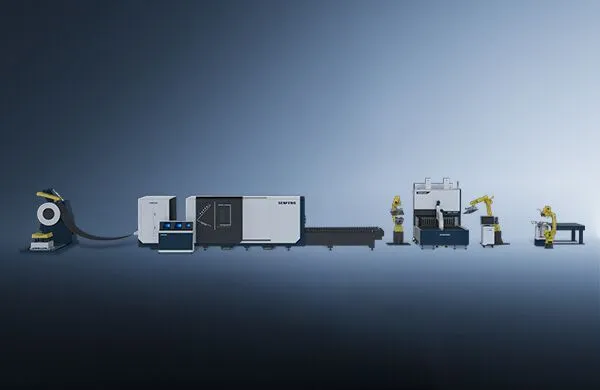

Production Line / Automation

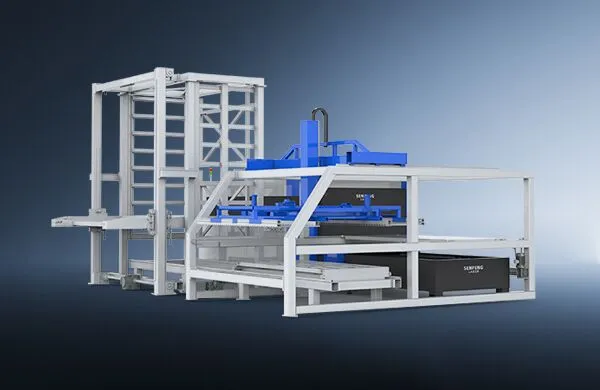

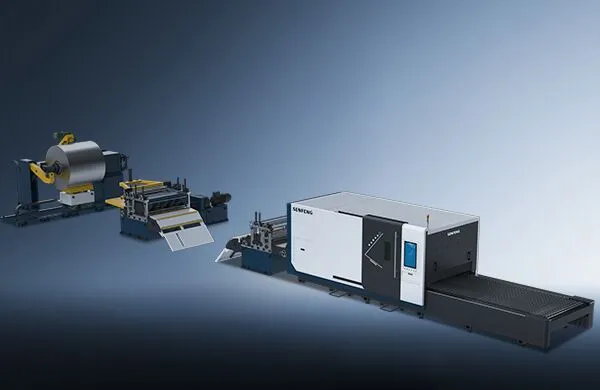

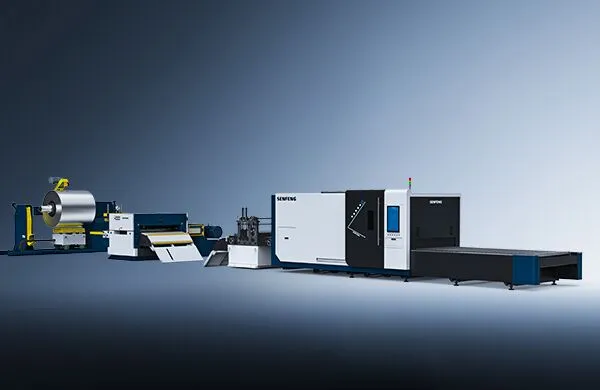

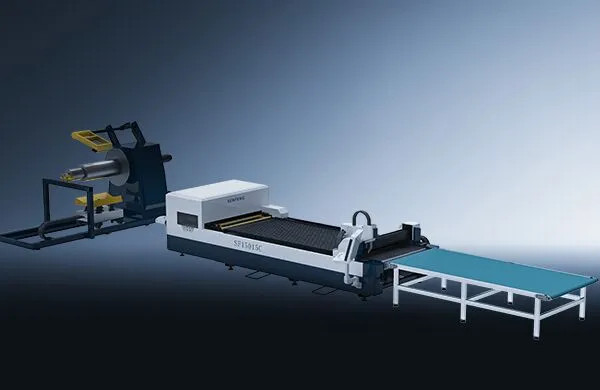

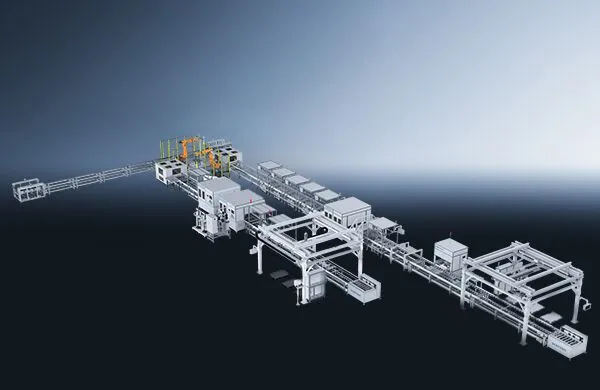

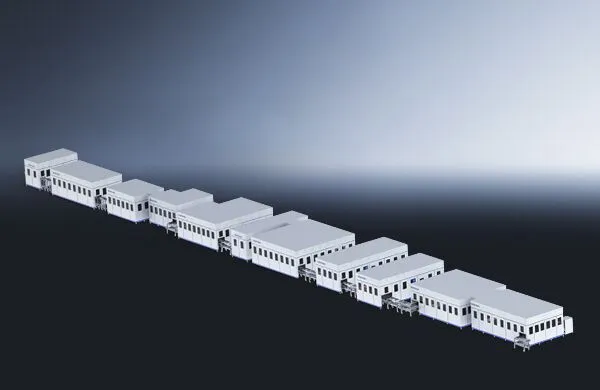

For sheet coils, front to end automation is made possible from decoiling, leveling, feeding, cutting, unloading, bending, welding and finished product stacking. The stereo pallet racks can make full use of space while storing sheets. In doing so, such centralized storage needs less footprint.

8 [layers] Stereo pallet racks

3000 [kg] Carrying capacity of each layer

3000*1500 [mm] Sheet size

10 [m/min] Warehouse-in/out speed

3000 [mm] Max feeding length

1500 [mm] Max width of sheet coil

3 [mm] Max thickness of coiled sheet

10 [T] Max weight of sheet coil

1.5-6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

1.5 [kW] Laser power

3000*1500 [mm] Working area

0.6-1.2 [mm] Thickness of sheet coil

10 [T] Max weight of sheet coil

6 [kW] Laser power

4000*2000 [mm] Working area

8-14 [mm] Thickness of coiled sheet

20 [T] Max weight of sheet coil

3-6 [kW] Laser power

4000*1500 [mm] Max working area

0.6-2 [mm] Thickness of sheet coil

10 [T] Max weight of sheet coil

Production Line / New Energy Line

12~24 [PPM] Total capacity

≥99.5 [%] Final excellent rate

≥90 [%] Machine utilization rate

Equipment Capacity: 12~24 PPM

Overall Line Yield: ≥99%

Overall Line Utilization Rate: ≥98%

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470