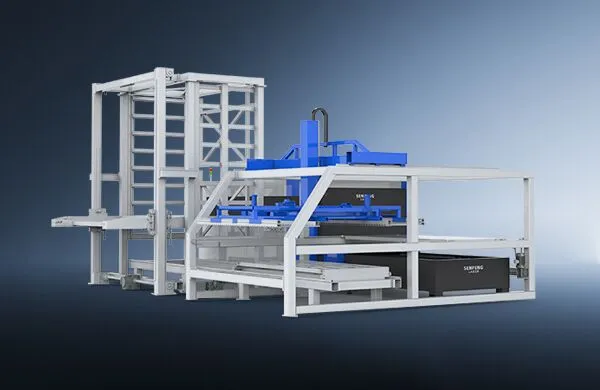

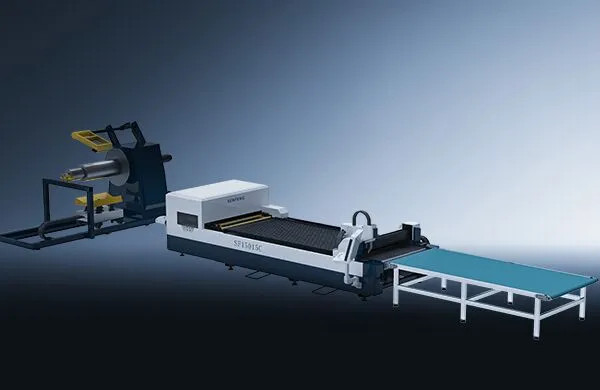

Laser Sheet Cutter with Loading and Unloading System

Laser Sheet Cutter with Loading and Unloading System

8 [layers] Stereo pallet racks

3000 [kg] Carrying capacity of each layer

3000*1500 [mm] Sheet size

10 [m/min] Warehouse-in/out speed

Technical Parameters

| Each Parts | Item | Technical Parameters |

| Storage Unit | Number of Layers of Pallet Racks | 8 |

| Layer-to-layer Height (mm) | 360 | |

| Stack-up Height of Each Layer (mm) | 280 (with wooden pallet) | |

| Carrying Capacity of Each Layer (kg) | 3000 | |

| Loading & Unloading Unit | Running Speed of Trolley (m/min) | 2-15 |

| Lifting/Translation Speed of Mechanical Arm (m/min) | 12/60 | |

| Warehouse-in/out Speed (m/min) | 10 | |

| Cutting Unit | Laser Power (kW) | 6 |

| Max Size of Sheet (mm) | 3000*1500 | |

| Min Size of Sheet (mm) | 800*800 | |

| Sheet Thickness (mm) | 0.8-12 | |

| X/Y-axis Positioning/Repositioning Accuracy (mm) | ±0.05/±0.02 | |

| Max No-load Speed (m/min) | 130 | |

| Max Load of Platforms (kg) | 2000 |

Competitive Strengths

⇲ Loading & unloading devices

* Vacuum suction cups used for loading. The unloading fork has smooth surface and minimal contact area with sheets to avoid them from scratch

* Loading & unloading robotic arm is made of high-strength steel pipes and quality steel plates, then, which will go through stress relief after overall welding, for high rigidity and precision

* Sheet handling trolley is driven by servo motor and speed reducer while lifting up/down and warehousing-in/out, in a word, it can move rapidly at high positioning accuracy

* Pallet rack lifter is also equipped with synchronized balance cylinder to keep itself more stable during quick lifting and avoid vibrations

⇲ Safety fence

Safety fence around the production line can prevent unauthorized access and avoid unexpected downtime

⇲ Heavy-duty thermal isolated hollow bed

* Laser cutting machine’s bed is fully hollow, with no internal connection. Such structure helps to cut off heat transfer and extend its lifespan

* Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Intelligent spiral negative-pressure dust removal

Laser cutting machine can open and close air outlets based on cutting position. Combined with bottom sealing structure, it can cut with smoke-free effects

⇲ Loading & unloading devices

* Vacuum suction cups used for loading. The unloading fork has smooth surface and minimal contact area with sheets to avoid them from scratch

* Loading & unloading robotic arm is made of high-strength steel pipes and quality steel plates, then, which will go through stress relief after overall welding, for high rigidity and precision

* Sheet handling trolley is driven by servo motor and speed reducer while lifting up/down and warehousing-in/out, in a word, it can move rapidly at high positioning accuracy

* Pallet rack lifter is also equipped with synchronized balance cylinder to keep itself more stable during quick lifting and avoid vibrations

⇲ Safety fence

Safety fence around the production line can prevent unauthorized access and avoid unexpected downtime

⇲ Heavy-duty thermal isolated hollow bed

* Laser cutting machine’s bed is fully hollow, with no internal connection. Such structure helps to cut off heat transfer and extend its lifespan

* Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Intelligent spiral negative-pressure dust removal

Laser cutting machine can open and close air outlets based on cutting position. Combined with bottom sealing structure, it can cut with smoke-free effects

⇲ Visually displayed interface

Show the debugging, setting, manual operation and other functions on touch screen for simple operation

⇲ Demonstration memory programming

Switch between automatic and manual mode at will, adapting to different working states

⇲ Intelligent start and stop

No need for manual control, make process transition smoother, save energy and protect environment well

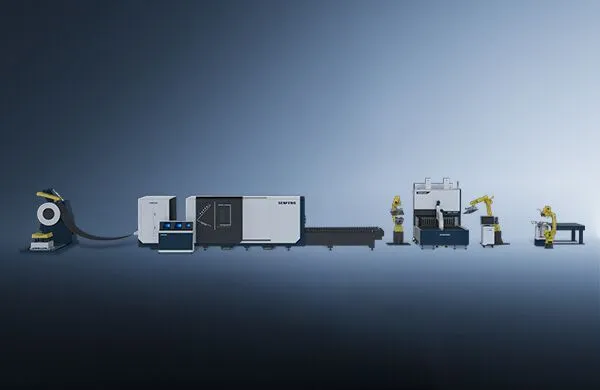

⇲ One-to-many operation

Its modular expansion allows users to freely combine according to their needs. A single loading & unloading system can serve multiple cutting machines at the same time, maximizing factory space

⇲ Personalized customization

The layer number of pallet racks can be tailored. We can provide individual solutions for users

⇲ MES integration

Reserve interfaces to dock with user’s MES system, as thus, prepare for the establishment of intelligent and digital workshops

Recent Posts

Archives

Categories

Related Products

8 [layers] Stereo pallet racks

3000 [kg] Carrying capacity of each layer

3000*1500 [mm] Sheet size

10 [m/min] Warehouse-in/out speed

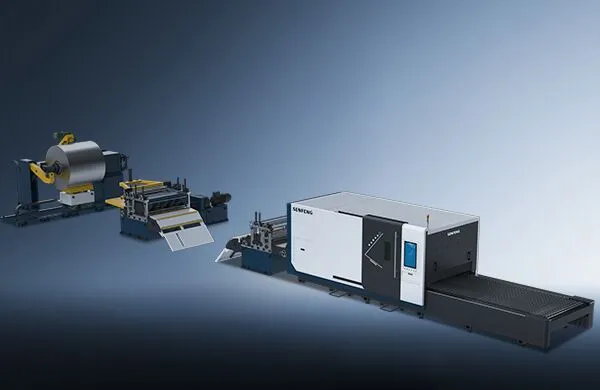

3000 [mm] Max feeding length

1500 [mm] Max width of sheet coil

3 [mm] Max thickness of coiled sheet

10 [T] Max weight of sheet coil

1.5-6 [kW] Laser power

3000*1500 [mm] Working area

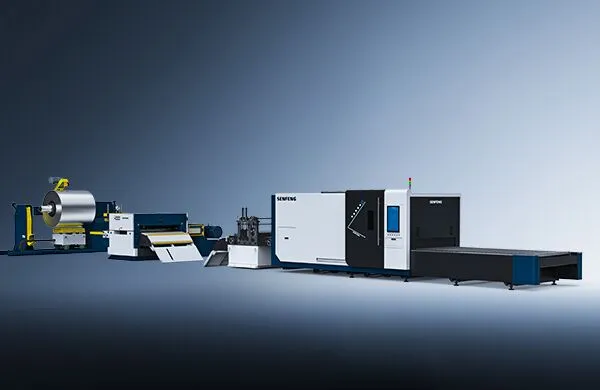

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

1.5 [kW] Laser power

3000*1500 [mm] Working area

0.6-1.2 [mm] Thickness of sheet coil

10 [T] Max weight of sheet coil

6 [kW] Laser power

4000*2000 [mm] Working area

8-14 [mm] Thickness of coiled sheet

20 [T] Max weight of sheet coil

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments