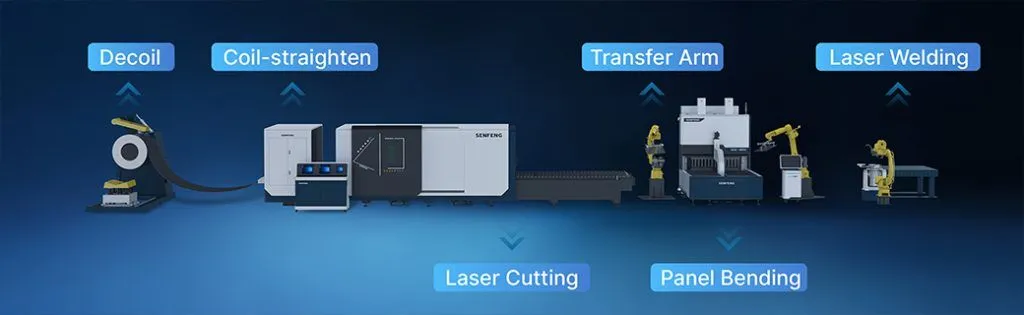

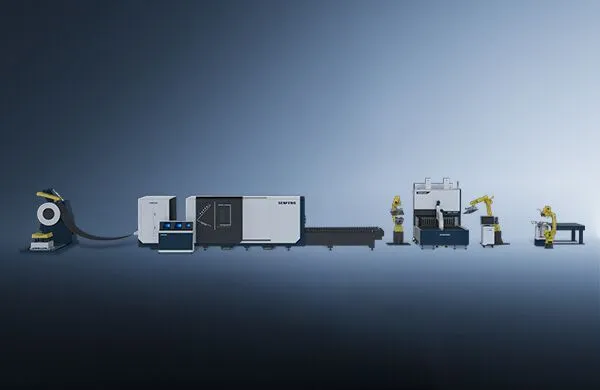

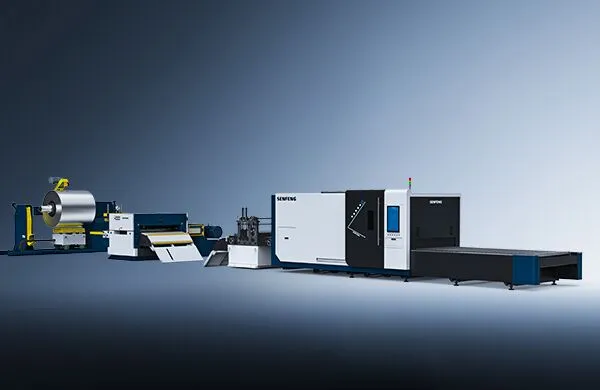

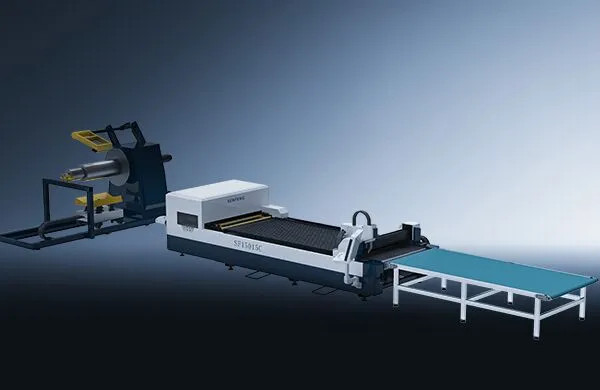

Flexible Metal Processing line TOP Series

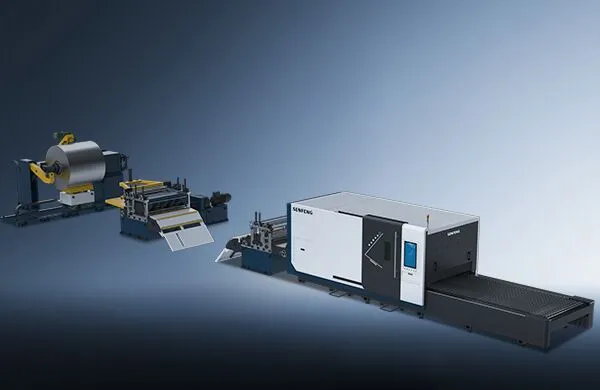

3000 [mm] Max feeding length

1500 [mm] Max width of sheet coil

3 [mm] Max thickness of coiled sheet

10 [T] Max weight of sheet coil

Technical Parameters

| Main Parameters | Model |

| SF1503CH-TOP RC3000W | |

| Max Size of Sheet Coil (L*W*T, mm) | 3000*1500*3 |

| Max Outer Diameter of Sheet Coil (mm) | 1400 |

| Standard Inner Diameter of Sheet Coil (mm) | 508 |

| Max Weight of Sheet Coil (T) | 10 |

| Leveling Accuracy (mm/m²) | ±2 |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 |

| Max Feeding Speed (m/min) | 10 |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) |

Competitive Strengths

⇲ Modular structure

We split the entire line into multiple modules, so that users may change its structure or add and subtract specific modules based on actual demands.

* Cutting module. Its laser blanking line combines decoiling, leveling, cutting and unloading together to make sheet coil cutting continuous

* Bending module. Flexible panel bender, together with universal bending dies, fits for bending the same workpiece in batch

* Welding module. Robot-assisted laser welding machine is featured by fast speed, high precision, nice-looking weld seams and basically no manual error

* Sorting module. Robot-assisted sorting system can complete sorting, transfer and stack-up work

⇲ Safety precautions

Photographic devices are outfitted to cover the whole production and monitor real-time status. As thus, workers will be informed of work progress even when standing in front of control console

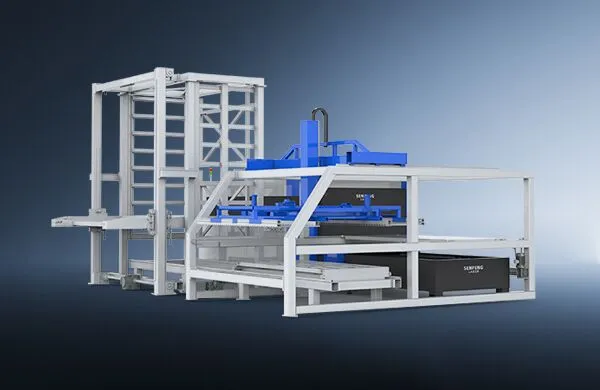

⇲ Stable machine tool

* The hollow machine tool bed is internally unconnected, which can cut off heat transfer, keep cutting precision high and prolong its service life

* Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Modular structure

We split the entire line into multiple modules, so that users may change its structure or add and subtract specific modules based on actual demands.

* Cutting module. Its laser blanking line combines decoiling, leveling, cutting and unloading together to make sheet coil cutting continuous

* Bending module. Flexible panel bender, together with universal bending dies, fits for bending the same workpiece in batch

* Welding module. Robot-assisted laser welding machine is featured by fast speed, high precision, nice-looking weld seams and basically no manual error

* Sorting module. Robot-assisted sorting system can complete sorting, transfer and stack-up work

⇲ Safety precautions

Photographic devices are outfitted to cover the whole production and monitor real-time status. As thus, workers will be informed of work progress even when standing in front of control console

⇲ Stable machine tool

* The hollow machine tool bed is internally unconnected, which can cut off heat transfer, keep cutting precision high and prolong its service life

* Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Visual interface

The operating interface is easy to understand, in this way, workers can get started quickly

⇲ Intelligent management

Collect and analyze data easily and take real-time monitoring of all parameters at work

⇲ High in flexibility

Connect and make all modules run and connect smoothly

⇲ Film lamination

Prevent metal surface from scratch after leveling

⇲ Ink jetting system

Generate labels in batch and make inkjet printing more precise and eco-friendly

⇲ Safety grating

Protect both man and machine by warding off accidents

⇲ Self-developed nesting software

Nest and typeset in full volume to maximize material utilization

⇲ Other extensible modules

Users are permitted to add and subtract cutting, bending, welding and sorting modules at will. We have also reserved interfaces docking with other intelligent systems like ERP, MES, SCM, in order that it may interconnect with other production lines to form intelligent manufacturing layout

Recent Posts

Archives

Categories

Related Products

8 [layers] Stereo pallet racks

3000 [kg] Carrying capacity of each layer

3000*1500 [mm] Sheet size

10 [m/min] Warehouse-in/out speed

3000 [mm] Max feeding length

1500 [mm] Max width of sheet coil

3 [mm] Max thickness of coiled sheet

10 [T] Max weight of sheet coil

1.5-6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

6 [kW] Laser power

3000*1500 [mm] Working area

0.6-3 [mm] Thickness of coiled sheet

10 [T] Max weight of sheet coil

1.5 [kW] Laser power

3000*1500 [mm] Working area

0.6-1.2 [mm] Thickness of sheet coil

10 [T] Max weight of sheet coil

6 [kW] Laser power

4000*2000 [mm] Working area

8-14 [mm] Thickness of coiled sheet

20 [T] Max weight of sheet coil

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments