Versatile CNC Lathe for Metal Machining and Custom Parts

Versatile CNC Lathe for Metal Machining and Custom Parts

360 [mm] Max cutting diameter

500 [mm] Max cutting length

50-4000 [r/min] Rotating speed of spindle

500 [kg] Max loading capacity

Technical Parameters

| Main Parameters | Model |

| SF-TCK50 | |

| Max/Standard Cutting Diameter (mm) | 360/240 |

| ax Cutting Length (mm) | 500 |

| Max Rotary Diameter (mm) | 500 |

| Spindle Speed (r/min) | 50-4000 |

| Chuck Diameter (mm) | 8″ (through hole) |

| X/Z-axis Rapid Speed (m/min) | 30/30 |

| X/Z-axis Travel (mm) | 200/550 |

| Tailstock Travel (mm) | 450 |

| Tool Size (mm) | 25*25 |

| Max Loading Capacity (kg) | 200-500 (vary from different shapes of workpieces) |

| Overall Dimensions (L*W*H, mm) | 2300*1700*1930 |

Competitive Strengths

⇲ Compact in structure

* Small in size and occupied area (only<4m2)

* Its fully-covered structure reserves front door to facilitate users to work inside

⇲ High-standard machine tool

The spindle, machine tool bed, tailstock and other components are reasonably matched to greatly improve the machine’s rigidity and keep heavy-duty cutting stable. As a result, the machining accuracy of this machine can reach IT6~IT7 level

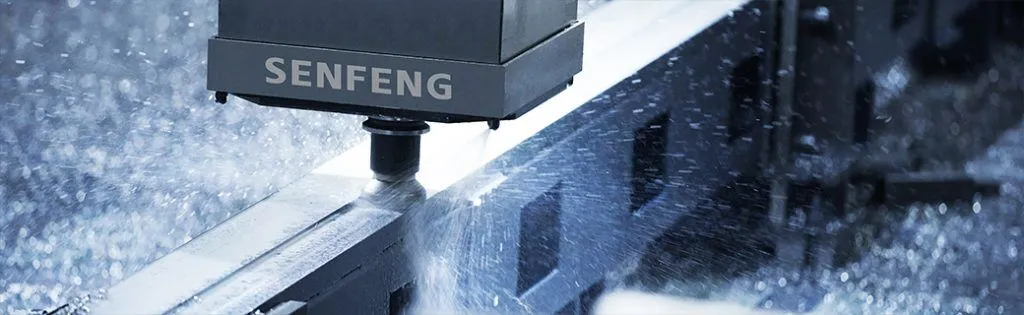

* Adopt 30°beveled integral bed, which makes the force more stable during cutting. The bed is made of high-density cast iron, featuring high strength and good vibration absorption

* As for spindle box, its motor uses pulley to drive itself to rotate, so as to reduce mechanical transmission of power loss and enable fast and smooth startup

* The tailstock body is dragged by means of the bed saddle and moves integrally on the sliding guides, which is more conducive to the cutting of long shaft parts

⇲ Linear guideway

We employ high-precision linear ball guideway, which has high feeding precision, low friction resistance, good rigidity, as well as high resistance to vibration and deformation

⇲ Hydraulic chuck

Come with 8-inch through-hole hydraulic chuck (φ210). It can be easily replaced in terms of various fixtures and fittings, with good adaptability to spare parts

⇲ Servo tool holder

Adopting sensitive proximity switch and well-designed electronic induction system, this tool holder is fast in response and tool changing and can run quietly at fast speed

⇲ Automatic chip removal system

We provide chain plate, scraper chip or magnetic scraper chip conveyor to collect and convey all cutting chips

⇲ Compact in structure

* Small in size and occupied area (only<4m2)

* Its fully-covered structure reserves front door to facilitate users to work inside

⇲ High-standard machine tool

The spindle, machine tool bed, tailstock and other components are reasonably matched to greatly improve the machine’s rigidity and keep heavy-duty cutting stable. As a result, the machining accuracy of this machine can reach IT6~IT7 level

* Adopt 30°beveled integral bed, which makes the force more stable during cutting. The bed is made of high-density cast iron, featuring high strength and good vibration absorption

* As for spindle box, its motor uses pulley to drive itself to rotate, so as to reduce mechanical transmission of power loss and enable fast and smooth startup

* The tailstock body is dragged by means of the bed saddle and moves integrally on the sliding guides, which is more conducive to the cutting of long shaft parts

⇲ Linear guideway

We employ high-precision linear ball guideway, which has high feeding precision, low friction resistance, good rigidity, as well as high resistance to vibration and deformation

⇲ Hydraulic chuck

Come with 8-inch through-hole hydraulic chuck (φ210). It can be easily replaced in terms of various fixtures and fittings, with good adaptability to spare parts

⇲ Servo tool holder

Adopting sensitive proximity switch and well-designed electronic induction system, this tool holder is fast in response and tool changing and can run quietly at fast speed

⇲ Automatic chip removal system

We provide chain plate, scraper chip or magnetic scraper chip conveyor to collect and convey all cutting chips

⇲ Instant data interaction

All configuration files are easily imported and exported, offering rich user-defined functions

⇲ Servo tool change at fast speed

An additional axis may be reserved to control tool holder. In doing so, tool changing speed will be raised by 20% at least

⇲ Tailor-made software

Users may choose some well-fitted software and set up personalized control system to make their cutting more targeted

⇲ High-end CNC system

Special for turning-milling composite machine tool, featured by fast response and user-centered operating menu to serve users well

⇲ Chucks of other specifications

Users are permitted to choose 10-inch through-hole, 8-inch solid and 10-inch through-hole chuck, so that different workpieces can be clamped easily

⇲ Oil mist collector

Collect and purify oil mist, water mist and other hazardous substances at work, in this way, minimize workshop pollution and protect workers well

Recent Posts

Archives

Categories

Related Products

360 [mm] Max cutting diameter

500 [mm] Max cutting length

50-4000 [r/min] Rotating speed of spindle

500 [kg] Max loading capacity

1000*550-1600*800 [mm] Worktable size

6000/8000 [r/min] Max speed of spindle

24 [cutter] Tool magazine capacity

2.5 [s] Tool changing time

- 123-456-7890

This Headline Grabs Visitors’ Attention

A short description introducing visitors to your business and the services you offer

About Us

Use this section to describe your company and the services you offer. You could share your company’s story and details about why you are in business. The goal is to create a connection with the visitor and give them confidence to work with you.

Our Services

This text briefly introduces visitors to your main services.

Service 1

A short description of the service and how the visitor will benefit from it.

Service 2

A short description of the service and how the visitor will benefit from it.

Service 3

A short description of the service and how the visitor will benefit from it.

Service 4

A short description of the service and how the visitor will benefit from it.

Why Choose Us

benefit 1

A short description of the benefit.

benefit 2

A short description of the benefit.

benefit 3

A short description of the benefit.

benefit 4

A short description of the benefit.

Client Testimonials

A Title to Turn the Visitor Into a Lead

© 2026 All Rights Reserved.

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments