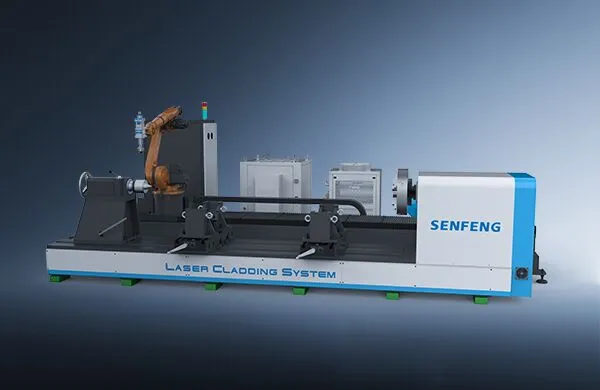

Open-style High Speed Laser Cladding Machine

6/12 [kW] Laser power

2 [T] Max load of table (no carrier roller)

6000 [mm] Max length of workpiece

Φ800 [mm] Max swing of workpiece

Technical Parameters

| Main Parameters | Model | |

| SFH3050 | SFH6050 | |

| Laser Power (kW) | 6/12 | 6/12 |

| Power Feeder | SENFENG dual-cylinder pneumatic powder feeder | SENFENG dual-cylinder pneumatic powder feeder |

| Laser Cladding Head | SENFENG high-speed laser cladding head | SENFENG high-speed laser cladding head |

| Control System | SENFENG intelligent cladding system | SENFENG intelligent cladding system |

| Max Load of Table (T) | 2 | 2 |

| Max Length of Workpiece (mm) | 3000 | 6000 |

| Max Clamping Diameter of Workpiece (mm) | Φ800 | Φ800 |

| Max Swing of Workpiece (mm) | Φ800 | Φ800 |

| Chuck (mm) | Φ500 (self-centering, three jaws) | Φ500 (self-centering, three jaws) |

Competitive Strengths

⇲ Deft design

* The open-style machine facilitates workers to get a whole picture of cladding process

* Its dust-proof design can protect all moving parts from dust, so as to raise running precision and service life of key transmission parts.

* The integrated self-lubrication system is able to lubricate all key moving parts quantificationally at regular period, in order to prolong lifespan.

* Its infinitely variable spindle has high output torque, high rigidity, stable running at low speed and easy speed regulation. The tailstock can move up and down at low failure rate.

⇲ Self-developed laser generator

Unlike others, it has higher electro-optical conversion rate, lower power dissipation and better laser beam.

⇲ Multi-purpose laser cladding head

* Our laser cladding head is compatible with annular, four-way, three-way or paraxial power feeding nozzle to offer various laser cladding crafts

* The special internally supercharged gas path and real-time monitoring lens are also used to prevent smoke dust & spatter and prolong service life

⇲ Dual-cylinder pneumatic powder feeder

* Driven by servo motor, the disc powder feeder is under SENFENG control system for remote control and stable powder feeding

* In addition, powder can be heated and added continuously (optional)

⇲ High-strength machine tool bed

The bed base, made of high-strength materials, is indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Deft design

* The open-style machine facilitates workers to get a whole picture of cladding process

* Its dust-proof design can protect all moving parts from dust, so as to raise running precision and service life of key transmission parts.

* The integrated self-lubrication system is able to lubricate all key moving parts quantificationally at regular period, in order to prolong lifespan.

* Its infinitely variable spindle has high output torque, high rigidity, stable running at low speed and easy speed regulation. The tailstock can move up and down at low failure rate.

⇲ Self-developed laser generator

Unlike others, it has higher electro-optical conversion rate, lower power dissipation and better laser beam.

⇲ Multi-purpose laser cladding head

* Our laser cladding head is compatible with annular, four-way, three-way or paraxial power feeding nozzle to offer various laser cladding crafts

* The special internally supercharged gas path and real-time monitoring lens are also used to prevent smoke dust & spatter and prolong service life

⇲ Dual-cylinder pneumatic powder feeder

* Driven by servo motor, the disc powder feeder is under SENFENG control system for remote control and stable powder feeding

* In addition, powder can be heated and added continuously (optional)

⇲ High-strength machine tool bed

The bed base, made of high-strength materials, is indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Record and return from breakpoint

It can record work state in time of unexpected power failure or alarm, then, return to original state after power recover

⇲ Detect water, power and gas signal in real time

Give alarm instantly and take related measures in case of any abnormality like too high water temperature or large current fluctuation

⇲ Failure diagnosis

Analyze all failures during running automatically because of its built-in failure diagnosis modules

⇲ Fully-covered protective chamber

Take a fully-covered structure into shape and reserve dust-proof interface to make cladding safer and more eco-friendly

⇲ Carrier roller

Deal with 3T workpiece (based on 2T)

⇲ CNC system

Provide other CNC systems to clad other complex spare parts incl. crank shaft and screw shaft

⇲ Wide-band quenching head

Carry out laser quenching on axial and other planelike workpieces

Recent Posts

Archives

Categories

Related Products

6/12 [kW] Laser power

20 [kg] Robot load (optional)

6000 [mm] Max length of workpiece

φ1500 [mm] Max swing of workpiece

6/12 [kW] Laser power

2 [T] Max load of table (no carrier roller)

6000 [mm] Max length of workpiece

Φ800 [mm] Max swing of workpiece

6 [kW] Laser power

20 [kg] Robot load (optional)

20-300 [μm] Powder size

150 [g/min] Max power feeding speed

6/12 [kW] Laser power

20 [kg] Robot load (optional)

6000 [mm] Max length of workpiece

φ1500 [mm] Max swing of workpiece

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments