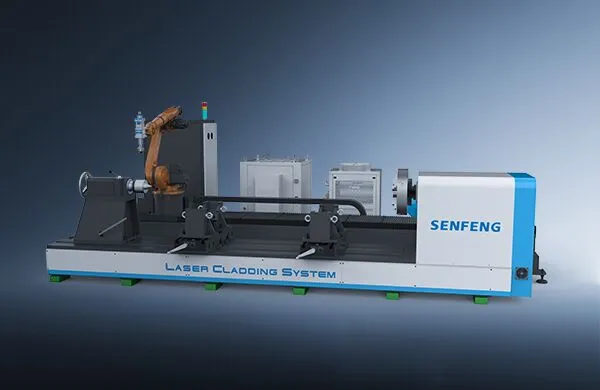

Mobile Robot Laser Cladding Machine SFMR02

Mobile Robot Laser Cladding Machine SFMR02

6 [kW] Laser power

20 [kg] Robot load (optional)

20-300 [μm] Powder size

150 [g/min] Max power feeding speed

Technical Parameters

| Main Parameters | Model |

| SFMR02 | |

| Laser Power (kW) | 6 |

| Max Load of Robot (kg) | 20 |

| Coverage Area of Robot (mm) | 1813 (vary from different brands) |

| Laser Spot Size (mm) | φ2-φ5 |

| Fiber Core Diameter (μm) | 600 |

| Number of Powder Feeder Cylinders | 2 |

| Volume of Single Cylinder (L) | 2.5 |

| Powder Size (μm) | 20-300 |

| Max Powder Feeding Speed (g/min) | 150 |

| Powder Feeding Error | ≤1% |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) |

Competitive Strengths

⇲ Deft design

* The highly integrated machine covers a small area for easy movement. Therefore, on-site cladding is made possible

* The robot is equipped with a mobile trolley on which there is lifting bracket used to keep the robot stable at work, so as to make sure of cladding precision

⇲ Self-developed laser generator

Unlike others, it has higher electro-optical conversion rate, lower power dissipation and better laser beam

⇲ Multi-purpose laser cladding head

It’s annular cladding nozzle and powder separator offer high-quality cladding together with multi-layer protective lens that can prevent smoke dust, spatter and water

⇲ Dual-cylinder pneumatic powder feeder

It is driven by smart control system and servo motor, just for stable powder feeding. With double transparent powder cylinders and powder mixing, you can visually observe powder residue, mix powders and avoid possible blockage.

⇲ Exclusive voltage stabilizer

It provides over-voltage, open-phase, phase sequence and mechanical failure protection. While withstanding transient overload, the stabilizer is free from waveform distortion, and keeps voltage adjustment more stable

⇲ Deft design

* The highly integrated machine covers a small area for easy movement. Therefore, on-site cladding is made possible

* The robot is equipped with a mobile trolley on which there is lifting bracket used to keep the robot stable at work, so as to make sure of cladding precision

⇲ Self-developed laser generator

Unlike others, it has higher electro-optical conversion rate, lower power dissipation and better laser beam

⇲ Multi-purpose laser cladding head

It’s annular cladding nozzle and powder separator offer high-quality cladding together with multi-layer protective lens that can prevent smoke dust, spatter and water

⇲ Dual-cylinder pneumatic powder feeder

It is driven by smart control system and servo motor, just for stable powder feeding. With double transparent powder cylinders and powder mixing, you can visually observe powder residue, mix powders and avoid possible blockage.

⇲ Exclusive voltage stabilizer

It provides over-voltage, open-phase, phase sequence and mechanical failure protection. While withstanding transient overload, the stabilizer is free from waveform distortion, and keeps voltage adjustment more stable

⇲ User-friendly operation

The interface is easy to operate. That is, human-machine interaction, laser generator and powder feeding can be totally controlled on the CNC system interface.

⇲ Adjust parameters in real time

Laser power and powder feeding speed are adjusted in real time. In other words, you can change cladding parameters at work, with no need for shutdown.

⇲ Failure diagnosis

It may detect and output signal feedback in real time. In the event of a failure, automatic alarm will be given in time.

⇲ Fully-covered protective sheet metals

Users are allowed to tailor protective sheet metals outfitted with remote start/stop button and monitoring modules to show actual running state of the machine

⇲ Additional shaft and other toolings

Dual-axis positioner, agricultural tool and other toolings are also available to deal with various workpieces

⇲ Inner-hole cladding head

Clad inner hole with min diameter of φ60mm

⇲ Offline software

Offline programming available to help out with the programming of special-shaped workpieces

Recent Posts

Archives

Categories

Related Products

6/12 [kW] Laser power

20 [kg] Robot load (optional)

6000 [mm] Max length of workpiece

φ1500 [mm] Max swing of workpiece

6/12 [kW] Laser power

2 [T] Max load of table (no carrier roller)

6000 [mm] Max length of workpiece

Φ800 [mm] Max swing of workpiece

6 [kW] Laser power

20 [kg] Robot load (optional)

20-300 [μm] Powder size

150 [g/min] Max power feeding speed

6/12 [kW] Laser power

20 [kg] Robot load (optional)

6000 [mm] Max length of workpiece

φ1500 [mm] Max swing of workpiece

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments