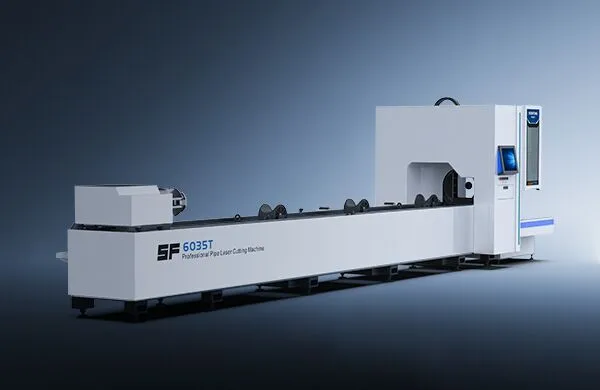

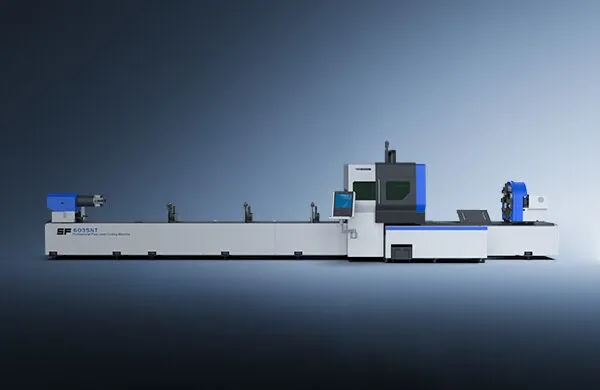

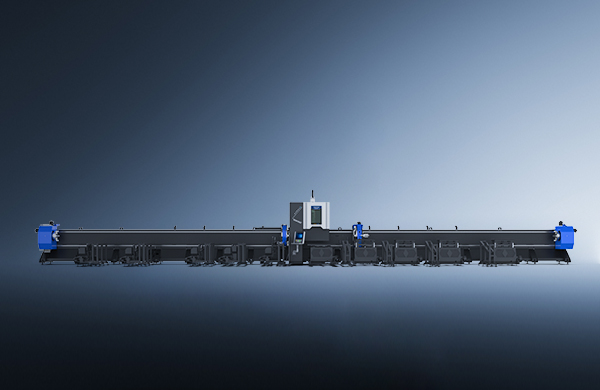

6m Laser Tube Cutter with Dual Chucks

1.5-6 [kW] Laser power

6000 [mm] Max length of tube

6-360 [mm] Tube size

80-500 [kg] Max weight of tube

Technical Parameters

| Main Parameters | Model | ||||

| SF6012T | SF6016T | SF6020T | SF6024T | SF6035T | |

| Laser Power (kW) | 1.5-3 | 1.5-3 | 1.5-6 | 1.5-6 | 1.5-6 |

| Max Length of Tube (mm) | 6000 | 6000 | 6000 | 6000 | 6000 |

| Scope of Tube Size (mm) | Φ6~120 | Φ10~160 | Φ10~220 | Φ10~240 | Φ20~360 |

| □6*6~120*120 | □10*10~160*160 | □10*10~150*150 | □10*10~240*240 | □20*20~360*360 | |

| Max Weight of Tube (kg) | 80 | 150 | 150 | 250 | 500 |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 |

| Max No-load Speed (m/min) | 150 | 100 | 100 | 100 | 60 |

| Max Rotating Speed of Chucks (r/min) | 180 | 140 | 100 | 100 | 60 |

| Overall Dimensions (L*W*H, mm) | 8900*2100*2100 | 8900*2100*2100 | 9260*1900*2280 | 9260*1900*2280 | 9500*2050*2550 |

| Power Supply | Three-phase 380V, 50Hz/60Hz | ||||

Competitive Strengths

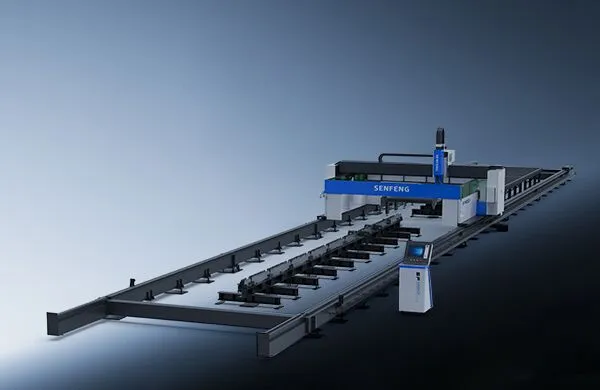

⇲ Tried-and-tested design

Semi-enclosed structure at high level of integration

Two pneumatic self-centering chucks, with unique craft for ultra-short tailing

High-strength machine tool, featured by shock absorption, stability and durability

Follow-up/vari-pitch support available to prevent any deviation caused by tube swing up and down

⇲ Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high acceleration (1.2G) and positioning accuracy (±0.02mm).

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Tried-and-tested design

Semi-enclosed structure at high level of integration

Two pneumatic self-centering chucks, with unique craft for ultra-short tailing

High-strength machine tool, featured by shock absorption, stability and durability

Follow-up/vari-pitch support available to prevent any deviation caused by tube swing up and down

⇲ Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high acceleration (1.2G) and positioning accuracy (±0.02mm).

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

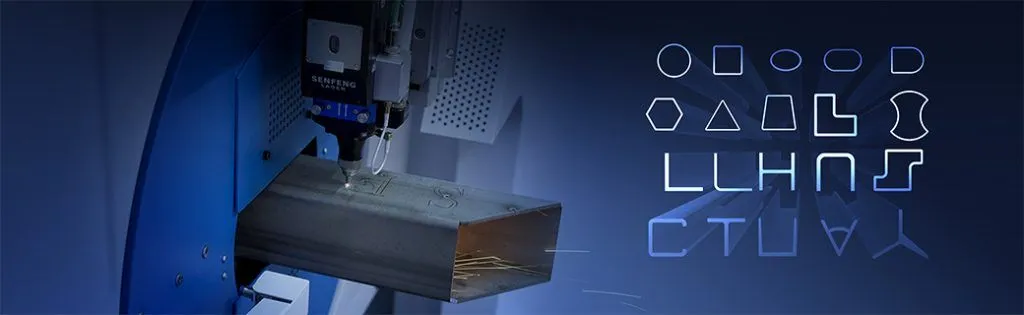

⇲ Cutting craft library

Easy to export and store cutting crafts for invoking anytime

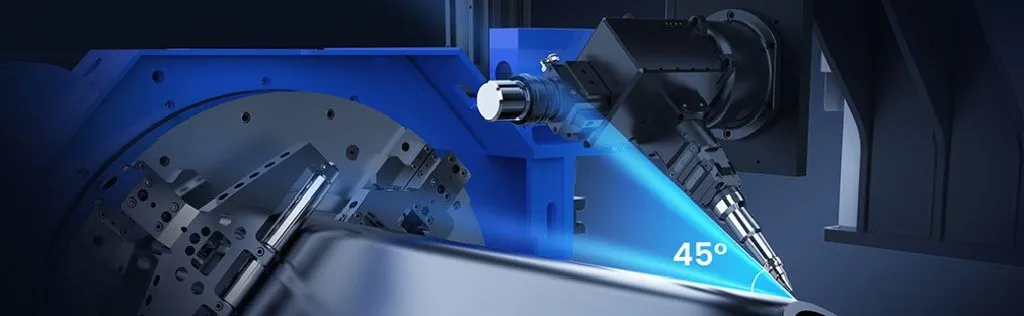

⇲ Corner cutting

Accept conventional and special tubes, for higher quality of corner cutting

⇲ Real-time deviation compensation

Lower demands on tube quality and raise piercing precision sharply

⇲ Innovative loading device

It comes standard with turnover plate to unload 2000mm long tube. But, users may apply for other fully-/semi-automatic loading devices as optional accessories. Basically no manual operation.

Recent Posts

Archives

Categories

Related Products

1.5-3 [kW] Laser power

6200 [mm] Max length of tube

16-80 [mm] Tube size

80 [kg] Max weight of tube

12-30 [kW] Laser power

28000*3000 [mm] Working area

35-50 [mm] Max sheet thickness

50 [m/min] Max no-load speed

1.5-6 [kW] Laser power

6000 [mm] Max length of tube

6-360 [mm] Tube size

80-500 [kg] Max weight of tube

1.5-6 [kW] Laser power

6000-12000 [mm] Max length of tube

20-360 [mm] Tube size

250-1000 [kg] Max weight of tube

6-20 [kW] Laser power

12000 [mm] Max length of tube

50-500 [mm] Tube size

2000 [kg] Max weight of tube

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments