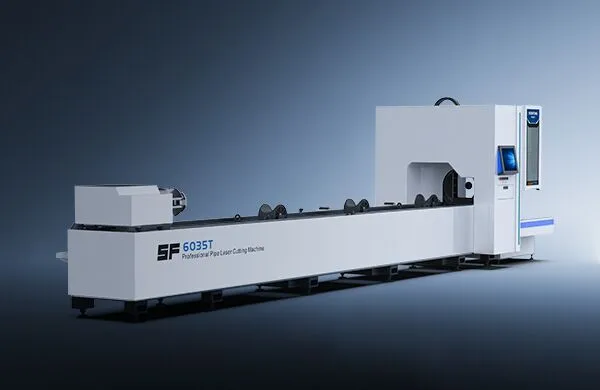

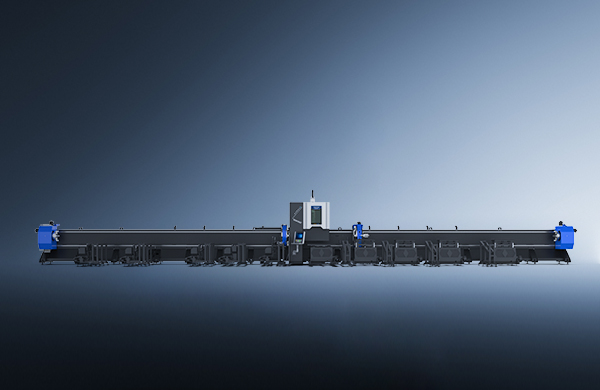

6-12m Laser Tube Cutter with Three Chucks

1.5-6 [kW] Laser power

6000-12000 [mm] Max length of tube

20-360 [mm] Tube size

250-1000 [kg] Max weight of tube

Technical Parameters

| Main Parameters | Model | ||||

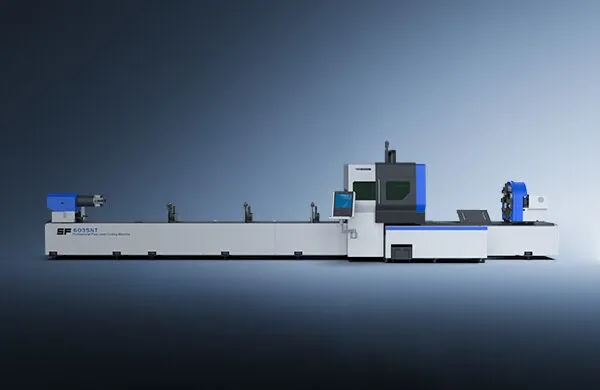

| SF6024NT | SF6035NT | SF9024NT | SF9035NT | SF12035NT | |

| Laser Power (kW) | 1.5-6 | 1.5-6 | 1.5-6 | 1.5-6 | 1.5-6 |

| Max Length of Tube (mm) | 6000 | 6000 | 9000 | 9000 | 12000 |

| Scope of Tube Size (mm) | Φ20~240 □20*20~230*230 |

Φ20~360 □20*20~360*360 |

Φ20~240 □20*20~230*230 |

Φ20~360 □20*20~360*360 |

Φ50~360 □50*50~360*360 |

| Max Weight of Tube (kg) | 250 | 1000 | 250 | 1000 | 1000 |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 |

| X/Y-axis Repositioning Accuracy (mm) | ±0.03 | ±0.03 | ±0.03 | ±0.03 | ±0.03 |

| Max No-load Speed (m/min) | 75 | 60 | 75 | 60 | 60 |

| Max Rotating Speed of Chucks (r/min) | 100 | 60 | 100 | 60 | 60 |

| Overall Dimensions (L*W*H, mm) | 13350*2750*2615 | 13500*2750*3390 | 16500*2750*2615 | 16500*2750*3390 | 19500*2750*3390 |

| Power Supply | Three-phase 380V, 50Hz/60Hz (custom-made) | ||||

Competitive Strengths

⇲ Tried-and-tested design

Semi-enclosed structure at high level of integration

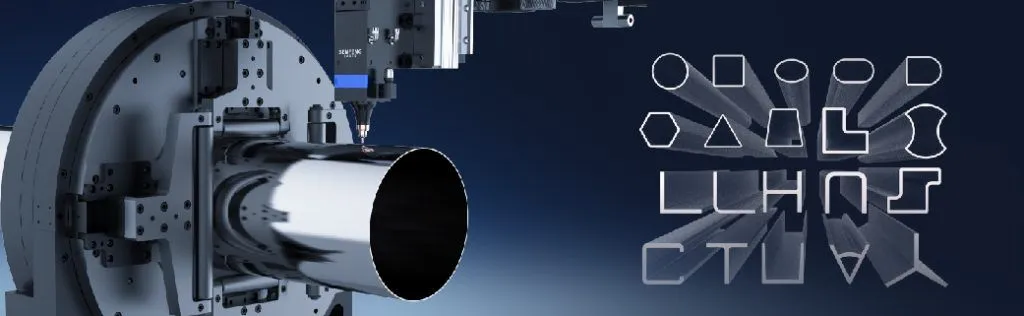

Three square-hole chucks to expand its clamping range

All-optical cutting head with autofocus and auto obstacle avoidance

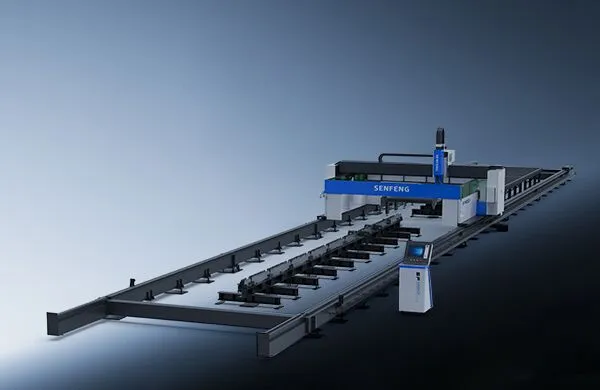

Horizontal machine tool, featuring heavy loads, modular structure and coaxial treatment

Follow-up support available to protect cutting precision from tube sagging

⇲ Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high positioning accuracy (±0.03mm)

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

⇲ Tried-and-tested design

Semi-enclosed structure at high level of integration

Three square-hole chucks to expand its clamping range

All-optical cutting head with autofocus and auto obstacle avoidance

Horizontal machine tool, featuring heavy loads, modular structure and coaxial treatment

Follow-up support available to protect cutting precision from tube sagging

⇲ Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high positioning accuracy (±0.03mm)

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like high annealing and aging treatment

The bus-based CNC system, with simple interface, is easy to operate and learn because of its high degree of intelligence. It can also support files in igs, sat, jhb and other formats.

⇲ Automatic nesting

Raise tube utilization rate and save raw materials to the utmost

⇲ 7-axis pulling

Innovative craft for dynamic cutting with 0 tailing

⇲ Real-time deviation compensation

Lower demands on tube quality and raise piercing precision sharply

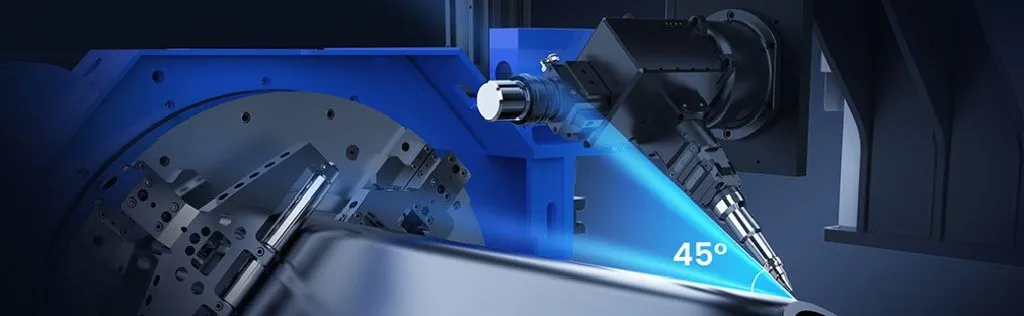

⇲ Bevel cutting (optional)

Cut tubes into ±45°bevel for easy subsequent welding

⇲ Innovative loading device

It comes standard with turnover plate to unload 2000mm long tube. But, users may apply for other fully-/semi-automatic loading & unloading devices as optional accessories. Basically no manual operation.

Recent Posts

Archives

Categories

Related Products

1.5-3 [kW] Laser power

6200 [mm] Max length of tube

16-80 [mm] Tube size

80 [kg] Max weight of tube

12-30 [kW] Laser power

28000*3000 [mm] Working area

35-50 [mm] Max sheet thickness

50 [m/min] Max no-load speed

1.5-6 [kW] Laser power

6000 [mm] Max length of tube

6-360 [mm] Tube size

80-500 [kg] Max weight of tube

1.5-6 [kW] Laser power

6000-12000 [mm] Max length of tube

20-360 [mm] Tube size

250-1000 [kg] Max weight of tube

6-20 [kW] Laser power

12000 [mm] Max length of tube

50-500 [mm] Tube size

2000 [kg] Max weight of tube

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments