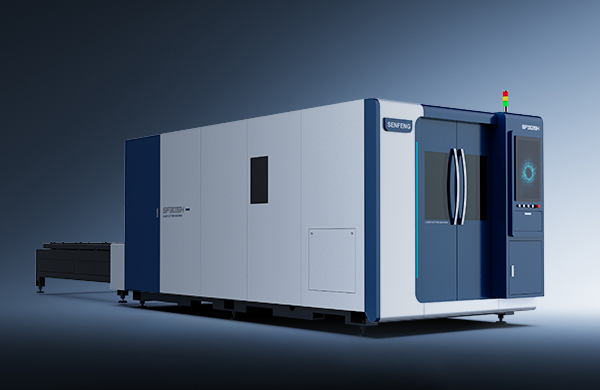

6kW-30kW High-power Plate Laser Cutter

6-30 [kW] Laser power

3080*1530-12550*2830 [mm] Plate size

180 [m/min] Max no-load speed

3000-16000 [kg] Load of platforms

Technical Parameters

| Main Parameters | Model | ||||||

| 3015H | 4020H | 6020H | 6025H | 8025H | 12025H | 12528H | |

| Laser Power (kW) | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 | 6-30 |

| Working Area (L*W, mm) | 3080*1530 | 4050*2030 | 6050*2030 | 6050*2530 | 8050*2530 | 12050*2530 | 12550* 2830 |

| X/Y-axis Positioning Accuracy (mm) | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 | ±0.05 |

| X/Y-axis Repositioning Accuracy (mm) | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 | ±0.02 |

| Max No-load Speed (m/min) | 180 | 180 | 180 | 180 | 180 | 169 | 180 |

| Max Load of Platforms (kg) | 3000 | 3200 | 4750 | 6000 | 8000 | 14000 | 16000 |

| Overall Dimensions (L*W*H, mm) | 8440*2270*2340 | 10876*3363*2515 | 14887*3363*2515 | 14740*3893*2515 | 19075*3893*2515 | 27927*3893*2515 | 28877*4233*2515 |

| Power Supply | Three-phase 380V, 50Hz/60Hz | ||||||

Competitive Strengths

⇲ Tried-and-tested design

Double exchange platforms available to save waiting time for loading & unloading

Adopt hollow machine tool and graphite plates as fire prevention

Aviation-grade AL beam at high strength, enabling its cutting into various shapes at high speed

Fully-enclosed structure, with flip-in air door and dust curtain for safety and environmental protection

⇲ Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high acceleration (2.8G) and positioning accuracy (±0.05mm).

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like 600° high annealing

⇲ Tried-and-tested design

Double exchange platforms available to save waiting time for loading & unloading

Adopt hollow machine tool and graphite plates as fire prevention

Aviation-grade AL beam at high strength, enabling its cutting into various shapes at high speed

Fully-enclosed structure, with flip-in air door and dust curtain for safety and environmental protection

⇲ Efficient drive system

We use integrated electronic components & precision guide rail and racks (100% match) to enable high acceleration (2.8G) and positioning accuracy (±0.05mm).

⇲ High-standard machine tool

Keep machine tool indeformable and unbroken at high temperature even after long-time use because of going through 7 standard processes like 600° high annealing

This professional CNC system is internally installed with many functions to easily cut plates at different thicknesses in different work conditions.

⇲ Lightning-fast piercing

Fast to pierce through thick plates at high quality

⇲ Visual detection of residues

Further use of residues to minimize plate waste

⇲ Visual collision avoidance

All-round monitoring without dead zone, making cutting safer

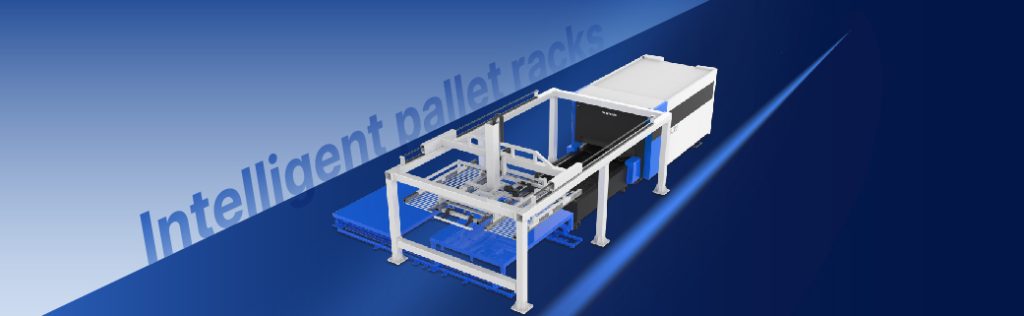

⇲ Intelligent pallet racks

Store, transfer, warehouse-in/out, load and unload plates automatically, making for efficiency gains and space utilization

Recent Posts

Archives

Categories

Related Products

6-60 [kW] Laser power

6000*3000-30000*4000 [mm] Plate size (extensible)

120 [m/min] Max no-load speed

7000-47000 [kg] Load of platform (extensible)

6-60 [kW] Laser power

6000*3000-30000*4000 [mm] Plate size if straight cut (extensible)

5400*2000-29400*3000 [mm] Plate size if beveling (extensible)

80 [m/min] Max no-load speed

7000-47000 [kg] Load of platform (extensible)

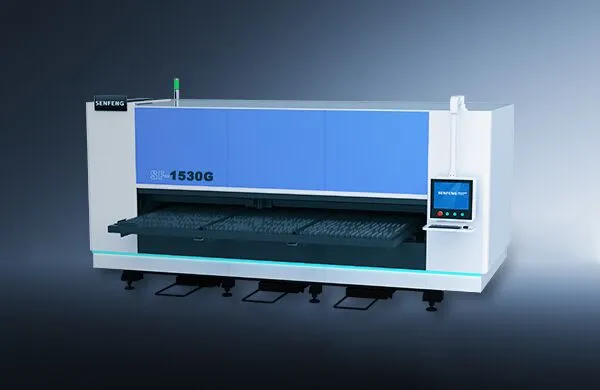

1.5-3 [kW] Laser power

3000*1500 [mm] Sheet size

80 [m/min] Max no-load speed

700 [kg] Load of platform

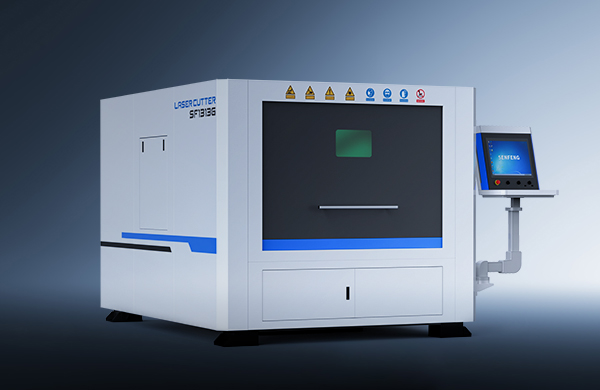

1.5-3 [kW] Laser power

1300*1300 [mm] Sheet size

80 [m/min] Max no-load speed

220 [kg] Load of platform

6-30 [kW] Laser power

3080*1530-12550*2830 [mm] Plate size

180 [m/min] Max no-load speed

3000-16000 [kg] Load of platforms

1.5-12 [kW] Laser power

3050*1530 [mm] Max sheet size

130 [m/min] Max no-load speed

700 [kg] Max load of platforms

Tautan terkait

PT GREATFIELD TECHNOLOGY INDONESIA

Hubungi Kami

Alamat:Ji.Komp.Kaouk Berlian No.59 blok A12, Desk/Kelurahan Kamal Muara, Kec.Penjaringan,Kota Adm. Jakarta Utara, Provinsi Dki Jakata,Kode Pos: 14470

Recent Comments